In the ever-evolving landscape of industrial equipment, choosing the right priming pump can significantly impact efficiency and performance in various applications. As we approach 2025, understanding the nuances that distinguish one priming pump from another is more crucial than ever. “Selecting the ideal priming pump is not just about specifications; it’s about aligning the pump’s capabilities with the operational demands of your project,” says Dr. Emily Carter, a leading expert in fluid dynamics and industrial machinery.

With advancements in technology and design, today's priming pumps offer a range of features that cater to diverse operational needs. Factors such as flow rate, material compatibility, and energy efficiency play a pivotal role in making the right choice. This guide aims to navigate through these critical considerations, providing insights that will empower consumers to make informed decisions when selecting a priming pump for their specific requirements.

As industries continue to push the envelope of efficiency and reliability, the significance of understanding and choosing the best priming pump cannot be overstated. By delving into the latest developments and expert recommendations, users can ensure that they are equipped with the tools necessary to meet their operational goals effectively in the coming years.

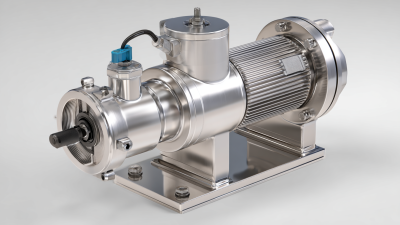

Priming pumps play a crucial role in a variety of industrial and agricultural applications by facilitating the initial movement of fluids. Understanding the types and functions of priming pumps can significantly enhance the efficiency of operations. There are primarily two categories of priming pumps: semi-positive displacement pumps and vacuum pumps. Semi-positive displacement pumps utilize a mechanical action to create a vacuum that draws fluid into the pump, while vacuum pumps operate by removing air from the system, thus reducing pressure and allowing atmospheric pressure to push fluid into the pump. According to a recent industry report from the Global Pump Market Analysis, priming pumps are expected to witness a steady growth rate of 3.2% annually through 2025, reflecting their increasing importance in fluid management.

When selecting a priming pump, consider the system's specific requirements such as flow rate, pressure, and the type of fluid being pumped. A well-suited pump can dramatically enhance efficiency, reduce energy consumption, and minimize maintenance costs. Tips for selection include evaluating the pump's material compatibility with the fluid to prevent corrosion and wear, as improperly matched materials can lead to early equipment failure. Additionally, examining the pump's operational ease, such as its self-priming capability, can save time and labor during installation and routine maintenance.

It’s essential to keep in mind that the application environment can greatly impact pump performance. For example, the presence of solids in wastewater applications often requires a different approach than that for clean water. To enhance the lifespan and reliability of your priming pump, ensure regular maintenance checks and adhere to manufacturer guidelines. Understanding these foundational elements will empower operators to make informed choices when integrating priming pumps into their systems.

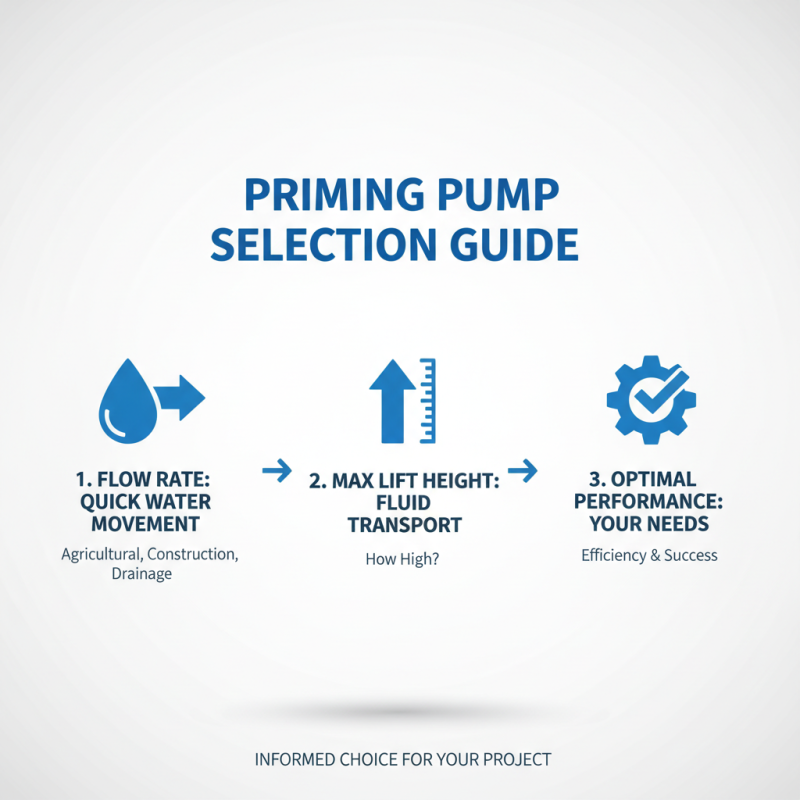

When selecting a priming pump, several key features must be considered to ensure optimal performance for your specific needs. First, the pump's flow rate is crucial; it dictates how quickly water will be moved through the system. Understanding the necessary flow rate for your applications—whether it's for agricultural uses, construction sites, or emergency drainage—will guide you in making an informed decision. Additionally, evaluating the pump's maximum lift height is important, as it indicates how high the pump can effectively transport fluids, which can vastly influence your project's success.

Another significant aspect is the material of the pump, which affects its durability and resistance to wear and tear. Priming pumps made from corrosion-resistant materials are ideal for environments where they will be exposed to harsh conditions or abrasive substances. Furthermore, consider the ease of maintenance; a pump designed for simple repair and part replacement can save both time and costs over its operational lifespan. Lastly, noise levels and energy efficiency are increasingly important in today’s market, as quieter and more efficient pumps significantly reduce environmental impact and operating costs.

When considering the comparative analysis of leading priming pump brands in 2025, it’s essential to focus on performance, reliability, and user feedback to make an informed decision. The top brands in the market have made significant strides in design and technology, resulting in pumps that are not only efficient but also durable. Many users emphasize the importance of ease of use and maintenance, noting that products with user-friendly interfaces and straightforward maintenance requirements tend to be favored.

Additionally, the build quality and materials of priming pumps are crucial factors that can affect their longevity and operational efficiency. In 2025, many brands have adopted innovative materials that reduce wear and tear while enhancing resistance to corrosion and other environmental factors. As such, a careful consideration of these elements, alongside a thorough review of customer testimonials and expert opinions, can provide valuable insights into which brands consistently deliver high-quality products. This comparative analysis helps consumers navigate the often overwhelming choices available in the market, ensuring they select a priming pump tailored to their specific needs and usage scenarios.

Maintaining a priming pump is essential to ensure its longevity and optimal performance. Regular inspection and cleaning of the pump are crucial. Begin by checking for any debris or blockages in the inlet strainer and the impeller. Clearing these obstructions can prevent overheating and reduce wear on the pump components. Additionally, monitoring the pump’s fluid levels and ensuring adequate lubrication can help to minimize friction and prolong the pump’s lifespan.

Another key aspect of maintenance is to adhere to a proper operating schedule. Avoid running the priming pump at extremes of pressure and flow. Overworking the pump not only accelerates wear but can also lead to catastrophic failure. It’s beneficial to keep detailed records of usage patterns and maintenance activities, as this information can provide insights into potential issues before they escalate. Regularly changing the oil and checking seals for wear can also make a significant difference in performance and durability. By implementing these practices, users can significantly extend the operational life of their priming pumps.

This chart illustrates the average lifespan and maintenance frequency of different priming pump types. The data shows the correlation between maintenance frequency and expected lifespan in years.

When selecting a priming pump, environmental considerations are more crucial than ever, particularly with the increasing emphasis on energy efficiency and eco-friendly options. According to a recent report by the U.S. Department of Energy, energy costs for pumping applications can account for up to 20% of a facility's total energy expenditures. As such, choosing a pump with high energy efficiency ratings can lead to significant cost savings over time, while simultaneously reducing the carbon footprint associated with these operations.

In addition to energy efficiency, the push for eco-friendly pumps is gaining momentum in the industry. Research from the Environmental Protection Agency highlights that pumps designed with sustainable materials and reduced emissions significantly lower the environmental impact of pumping systems. Features such as variable frequency drives (VFDs) not only enhance the operational efficiency of pumps but also enable them to adapt to varying loads, pushing energy consumption down by as much as 50%. By prioritizing these eco-friendly options, businesses can not only comply with increasing regulatory demands but also contribute to a more sustainable future.

| Pump Type | Energy Efficiency Rating | Flow Rate (GPM) | Material | Eco-Friendly Features | Price ($) |

|---|---|---|---|---|---|

| Self-Priming Centrifugal | A+ | 15 | Aluminum | Solar-powered option available | 250 |

| Diaphragm Pump | B | 10 | Polypropylene | Recyclable materials | 180 |

| Submersible Pump | A | 20 | Stainless Steel | Energy Star rated | 300 |

| Peristaltic Pump | A++ | 8 | FDA Approved Rubber | Minimal waste during operation | 350 |