In today’s competitive industrial landscape, the efficiency and performance of operations hinge significantly on the effectiveness of their pumping solutions. Industrial pumping solutions play a crucial role in various sectors, from manufacturing and construction to water treatment and oil & gas. The right pumping systems not only streamline processes but also contribute to significant energy savings and operational reliability. As industries evolve and face new challenges, understanding and implementing the best pumping technologies is essential.

In this guide, we will explore the top five industrial pumping solutions designed to enhance efficiency and performance across different applications. We will delve into the fundamental aspects of each solution, discussing their benefits, ideal use cases, and how they can be integrated into existing systems. Whether you are looking to reduce costs, improve reliability, or enhance your operational capacity, these solutions offer valuable insights and strategies for achieving your goals. Join us as we navigate through the key elements that could transform your industrial operations and lead you towards a more productive future.

Identifying your industrial pump requirements is crucial for optimizing performance. Various factors must be considered, including the type of fluid being pumped, viscosity, temperature, and required flow rate. Each application may demand specific pump designs, from centrifugal pumps for low-viscosity liquids to positive displacement pumps for thicker fluids.

Understanding these parameters allows businesses to select pumps that operate efficiently and effectively in their unique environments.

Additionally, assessing the overall system design can significantly impact pumping efficiency. This includes evaluating pipe sizes, layout, and any potential obstacles that could impede flow. Regular maintenance and monitoring of pump performance are also essential to ensure long-term reliability and efficiency. By prioritizing these requirements and insights, industries can enhance not only their pumping systems but also their overall operational performance.

When selecting the right pump type for specific applications and fluids, it is essential to consider the unique requirements of each industry. For instance,

the peristaltic hose pump is gaining traction, with the global market projected to grow from

$290 million in 2024 to $370 million by 2033, reflecting a

compound annual growth rate (CAGR) of 3.5%. This type of pump is ideal for transporting shear-sensitive fluids, making it a

go-to solution for industries such as pharmaceuticals and food processing.

Additionally, the residential water pump market is expected to experience similar growth, with values surging from approximately

$1.16 billion in 2024 to $15.85 billion by 2033 at a

CAGR of 3.6%. These pumps typically cater to household water supply needs, highlighting the importance of selecting

the appropriate type based on the specific requirements of a plumbing system or local regulations. By understanding the unique applications tied to each

pump type, industries can significantly enhance efficiency and performance while optimizing operational costs.

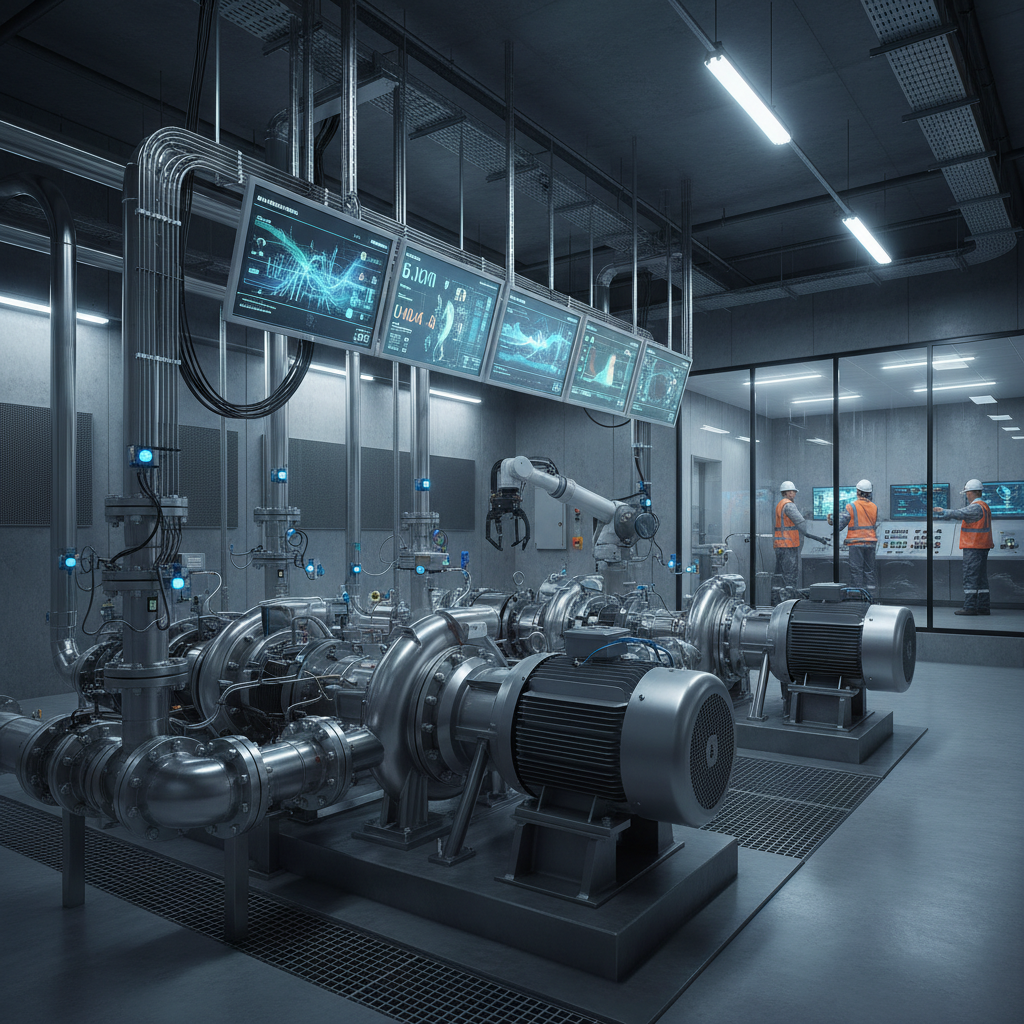

Implementing advanced control systems in industrial pumping solutions can significantly enhance efficiency and performance. These control systems utilize real-time data analytics and automation, allowing for precise monitoring and adjustment of pump operations. By integrating sensors and smart software, plants can respond dynamically to changes in system demand, ensuring that pumps operate at optimal levels. This not only maximizes energy efficiency but also reduces wear and tear on equipment, extending the lifespan of pumps and decreasing maintenance costs.

Moreover, advanced control systems facilitate predictive maintenance by analyzing performance trends and identifying potential issues before they escalate. This proactive approach minimizes downtime and ensures continuous operation, which is crucial for maintaining productivity in industrial environments. Additionally, with improved data visualization and user interfaces, operators can make informed decisions quickly, resulting in a more streamlined workflow. The adoption of these cutting-edge technologies ultimately positions companies to achieve greater operational efficiency and sustainability in their pumping processes.

The global magnetic pump market is poised for significant growth, expected to reach $960 million by 2033, up from $700 million in 2024, with a compound annual growth rate (CAGR) of approximately 3.6%. This upward trend highlights the importance of adopting regular maintenance practices to enhance pump life and reliability. Proper maintenance not only ensures operational efficiency but also minimizes the risk of unexpected downtime, which can severely impact productivity in industrial settings.

In addition to magnetic pumps, the helicopter Maintenance, Repair, and Overhaul (MRO) market is also on the rise, driven by the increasing demand for both commercial and military applications. The MRO market is predicted to grow across various helicopter types—including light and medium helicopters—indicating a diverse need for maintenance services. Regular checks and services such as line and base maintenance are crucial to ensure safety and efficiency. As the industry evolves, investment in reliable maintenance solutions will be critical for optimizing performance and extending the lifespan of pumping systems and aircraft alike.

In today’s industrial landscape, integrating automation technologies into pumping operations is not just a trend but a necessity. According to a report by Markets and Markets, the global industrial automation market is projected to reach $296.70 billion by 2026, growing at a CAGR of 9.2%. This increase emphasizes the critical role of automation in enhancing efficiency and performance in pump operations. By employing advanced automation systems, industries can achieve real-time monitoring and data analysis, allowing for proactive maintenance and reduced downtime.

Moreover, the benefits of integrating automation go beyond mere efficiency; they also enhance precision in operations. A study published by Research and Markets indicates that automated pumps can improve operational efficiency by up to 30%, significantly reducing energy consumption and operational costs. For example, the implementation of smart pump systems equipped with IoT technology enables better control over flow rates and pressures, tailored to the specific needs of processes. This not only streamlines operations but also minimizes wear and tear on equipment, ensuring longer lifespans and reduced replacement costs. The move towards automation in pumping operations showcases a robust pathway towards optimizing industrial performance and sustainability.