In the ever-evolving world of manufacturing and industrial processes, the efficiency and longevity of machinery heavily depend on the quality and functionality of their components. One critical area that demands attention is industrial pump parts. According to Dr. Emily Hawthorne, a renowned expert in fluid dynamics, "The right combination of industrial pump parts can significantly enhance operational efficiency and reduce downtime." This sentiment highlights the importance of selecting not just any components, but the very best parts suited to your specific industrial applications.

In this article, we delve into the top 10 essential industrial pump parts that are necessary for optimal performance. From seals and bearings to impellers and housings, each component plays a vital role in ensuring that pumps function smoothly and reliably. By emphasizing the importance of maintaining high-quality industrial pump parts, we can help professionals in the field make informed decisions that ultimately lead to improved productivity and reduced operational costs. Join us as we explore the intricate world of industrial pump components and their influence on overall system performance.

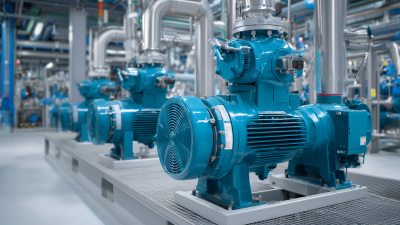

Industrial pumps are critical assets in various sectors, facilitating the movement of fluids and ensuring operational efficiency. When assessing performance, it's essential to understand that it's not solely the pump itself that matters, but also the quality and condition of its parts. Each component, from impellers to seals, plays a vital role in ensuring that the pump operates smoothly and reliably. Neglecting any part can lead to inefficiencies and increased downtime, ultimately affecting overall productivity.

Moreover, the significance of high-quality pump parts extends beyond mere functionality. They directly influence energy consumption and maintenance costs. For instance, a worn-out seal may cause leaks, leading to product loss and potential damage to other equipment. By investing in robust industrial pump parts, facilities can optimize performance while minimizing risks and expenses. Regular inspections and timely replacements of these components ensure a seamless flow of operations and enhance the longevity of the pump, contributing to a more sustainable industrial environment.

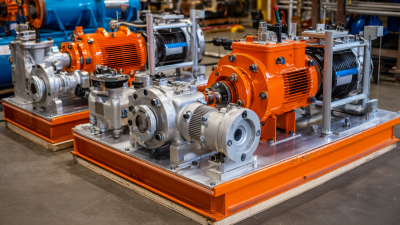

Industrial pumps play a crucial role in various sectors, including manufacturing, oil and gas, and water treatment. Understanding the key components that contribute to their optimal performance is essential for maintenance and operational efficiency. Among these components, the impeller, which converts rotational energy into kinetic energy, is often the heart of the pump. According to a report from the Fluid Control Institute, the design and material of the impeller can significantly impact the overall efficiency of a pump system, with well-designed impellers increasing efficiency by up to 30%.

Another vital part is the pump casing, which houses the impeller and helps to direct fluid flow. Its design affects both performance and durability, as pressure and flow characteristics are influenced by the casing's shape and size. The American Society of Mechanical Engineers (ASME) highlights that a well-engineered casing can reduce cavitation risks, which is essential for maintaining the longevity and functionality of the pump. Additionally, seals and bearings are crucial components that ensure reliable operation by preventing leaks and reducing friction, ultimately contributing to reduced maintenance costs and improved operational uptime. Together, these components underscore the intricate engineering behind industrial pumps and their critical contributions to system integrity and performance.

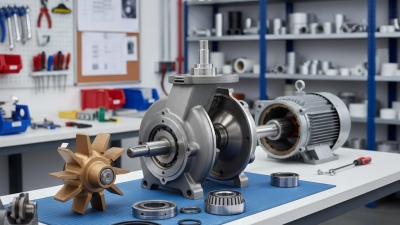

To enhance the efficiency and longevity of industrial pumps, the selection of high-quality components is crucial. One of the most vital parts is the seal, as it prevents leaks and ensures that the operational fluids remain contained within the system. A robust seal can significantly reduce maintenance needs and prolong the lifespan of the pump by minimizing wear and tear caused by fluid friction and leakage. Additionally, incorporating wear plates can protect critical areas from abrasion, thereby extending the life of the pump's components.

Another essential part for optimizing pump performance is the impeller. The design and material of the impeller directly impact the pump’s efficiency and flow rate. Using corrosion-resistant materials for the impeller enhances durability and aids in maintaining consistent performance under varying conditions. Coupled with a well-designed volute, these components work in tandem to improve hydraulic efficiency, which is key for reducing energy consumption and operational costs over time.

Lastly, proper bearings and shafts are essential for smooth operation and reduced vibration. Ensuring that these components are of high-quality construction helps in maintaining alignment and minimizing friction, which further contributes to a longer operational life and enhanced efficiency. By investing in these critical parts, facilities can optimize their pump systems, achieving both operational excellence and significant cost savings in the long run.

| Part Name | Function | Material | Maintenance Frequency | Lifespan (Years) |

|---|---|---|---|---|

| Impeller | Fluid movement | Stainless Steel | Annually | 5-10 |

| Seal | Prevents leaks | Rubber | Bi-annually | 1-3 |

| Bearing | Supports shaft rotation | Bronze | Every 2 years | 3-5 |

| Suction Strainer | Prevents debris intake | Stainless Steel | Quarterly | 5-7 |

| Casing | Houses internal components | Cast Iron | Every 5 years | 15-20 |

| O-Ring | Creates a seal | Nitrile | Annually | 2-5 |

| Diffuser | Directs flow | Plastic | Every 3 years | 4-6 |

| Shaft | Transmits power | Alloy Steel | Every 5 years | 10-15 |

| Motor | Drives the pump | Aluminum | Every 4 years | 15-20 |

| Control Unit | Regulates operation | Plastic/Metal | Every 3 years | 10-12 |

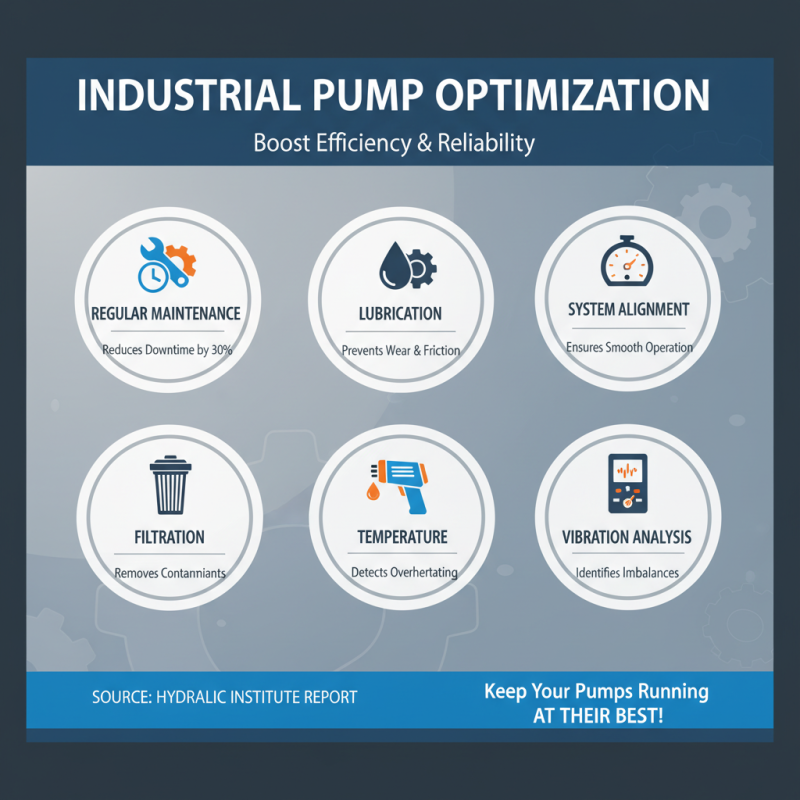

Maintaining optimal performance in industrial pumps is crucial for long-term operational efficiency and reliability. According to a report from the Hydraulic Institute, regular maintenance can reduce unexpected downtime by up to 30%, making it essential for industrial operations. To ensure your pumps are running at their best, it’s vital to focus on key maintenance practices.

First, always check and replace the pump seals at regular intervals. Worn seals can cause leaks and lead to significant performance issues. According to a recent study, over 70% of pump failures are attributed to seal and bearing wear. Additionally, ensure that the impeller is clean and free from debris, as this directly affects fluid dynamics and overall pump efficiency.

**Tip:** Implement a scheduled maintenance routine to regularly inspect and service pump components. Keeping an eye on vibration levels can also provide insights into potential issues before they escalate. Utilize vibration analysis tools to monitor pump performance and identify irregular patterns that may indicate failing components.

Furthermore, maintaining proper lubrication of all moving parts is essential. Proper oil levels and the right type of lubricant can enhance efficiency and prolong the life of your pump. The American Society of Mechanical Engineers recommends checking lubrication systems on a monthly basis to prevent wear and tear.

**Tip:** Use high-quality lubricants as specified by the equipment manufacturer, and adhere to recommended service timelines for optimal pump performance. Regularly analyzing fluid quality can also help in detecting contamination and ensuring that the pump operates smoothly.

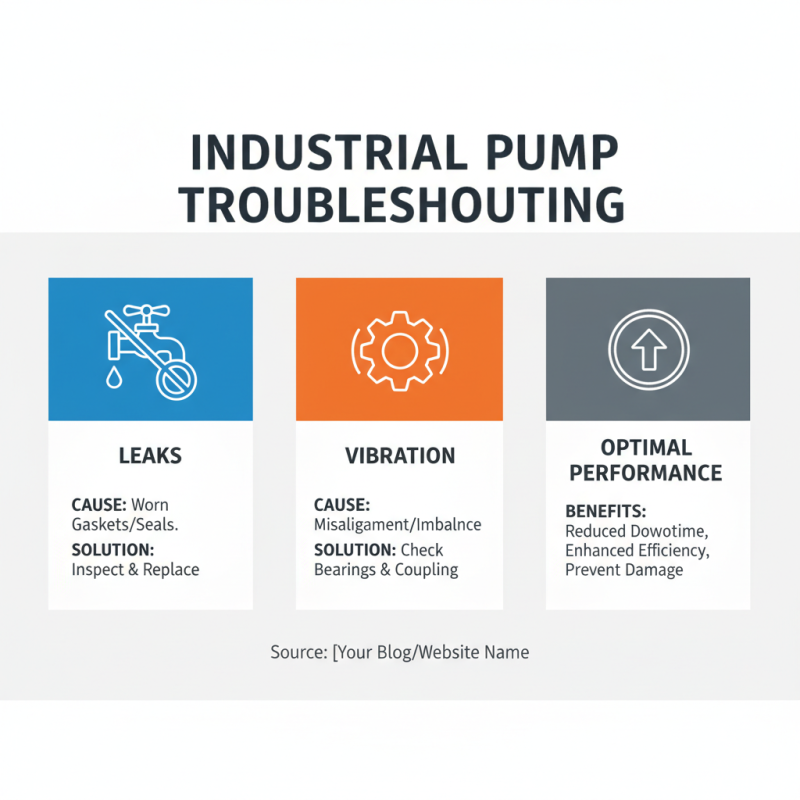

When it comes to industrial pumps, ensuring optimal performance often hinges on troubleshooting common issues related to pump parts and components. One prevalent problem is leaks, which can arise from worn gaskets or seals. Regularly inspecting and replacing these components can significantly reduce downtime and enhance efficiency. Additionally, vibration issues may indicate misalignment or imbalance in the rotating parts, necessitating a thorough inspection of bearings and coupling. Addressing these issues promptly can prevent further damage and maintain the operational integrity of the pump.

Another common concern is inadequate flow rates, which may stem from clogs or blockages in the impeller or piping systems. Regular maintenance, including cleaning and inspection, is vital to identify any restrictions early on. Furthermore, monitoring the power supply and ensuring that the motor is functioning correctly can help avoid performance-related issues. By systematically addressing these common problems, operators can achieve a more reliable and efficient pumping operation, ultimately leading to improved productivity in industrial processes.