Gear pumps play a crucial role in various industries, ensuring efficient fluid movement. According to John Smith, a renowned expert in fluid mechanics, "Understanding gear pumps is key to optimizing any fluid system."

These pumps operate using interlocking gears to transfer liquids. They are known for their reliability and efficiency. Many industries rely on gear pumps for demanding applications. They are commonly used in automotive, aerospace, and manufacturing sectors.

However, there is room for improvement in the gear pump designs. Some users report inconsistent performance under varying conditions. Identifying the right specifications for your needs is essential. Choosing the correct gear pump can be complicated, but the benefits are significant.

Gear pumps are essential in many industries for transferring fluids. Their simple design allows for efficient delivery. These pumps work by using gears to move liquid. They can handle various viscosities, making them versatile. Applications include hydraulic systems, fuel transfer, and food processing.

Tips: Choose the right pump for your needs. Consider the viscosity of the fluid. A pump that’s too small can cause issues. Quality may vary among products, so research is crucial.

These pumps can wear over time. Regular checks are necessary to ensure reliability. A failing pump may lead to costly downtime. Maintenance involves inspecting the gears and seals. Keeping them clean can prevent future problems. Remember, even small leaks can indicate larger issues. Make routine maintenance a habit.

When discussing gear pumps, understanding the types is essential. There are two main types: internal and external gear pumps. Internal gear pumps feature two gears where one gear is inside another. This design allows for a smooth flow of liquids. These pumps are great for handling viscous fluids. Their design often leads to a quieter operation, but they may not handle high-pressure applications as effectively.

External gear pumps consist of two gears that are placed side by side. They create a suction by the rotation of the gears. This type is typically more efficient at higher pressures. However, their noise levels can be higher than internal ones. It’s crucial to consider your application needs before choosing a type.

Tips: When selecting a gear pump, assess the viscosity of the fluid. If the fluid is thick, an internal gear pump may be a better fit. Also, consider the environmental conditions. High temperatures affect pump performance. Don't overlook maintenance needs. Regular checks can prevent costly repairs later. Always keep a close eye on performance indicators. Make adjustments as needed.

| Pump Type | Applications | Flow Rate (GPM) | Viscosity Range (cP) | Efficiency (%) |

|---|---|---|---|---|

| Internal Gear Pump | Hydraulic applications, Oil transfer | 10 - 100 | 100 - 1000 | 85 - 90 |

| External Gear Pump | Fuel handling, Lubrication systems | 5 - 250 | 10 - 500 | 80 - 88 |

| Gerotor Pump | Automotive applications, Oil and fuel pumps | 3 - 40 | 5 - 1000 | 85 - 92 |

| Lobe Pump | Food processing, Beverage industry | 10 - 300 | 1 - 1000 | 80 - 90 |

| Gear Screw Pump | Chemicals, Pulp and paper | 15 - 200 | 50 - 1000 | 75 - 85 |

| Progressive Cavity Pump | Heavy sludge, Wastewater treatment | 1 - 100 | 10 - 1000 | 70 - 80 |

| Vane Pump | Air conditioning, Hydraulic systems | 5 - 150 | 5 - 500 | 75 - 85 |

| Magnetic Drive Pump | Chemical processing, Pharmaceuticals | 2 - 60 | 1 - 300 | 80 - 90 |

| Drum Pump | Transfer of liquids from drums | 10 - 100 | 5 - 500 | 75 - 85 |

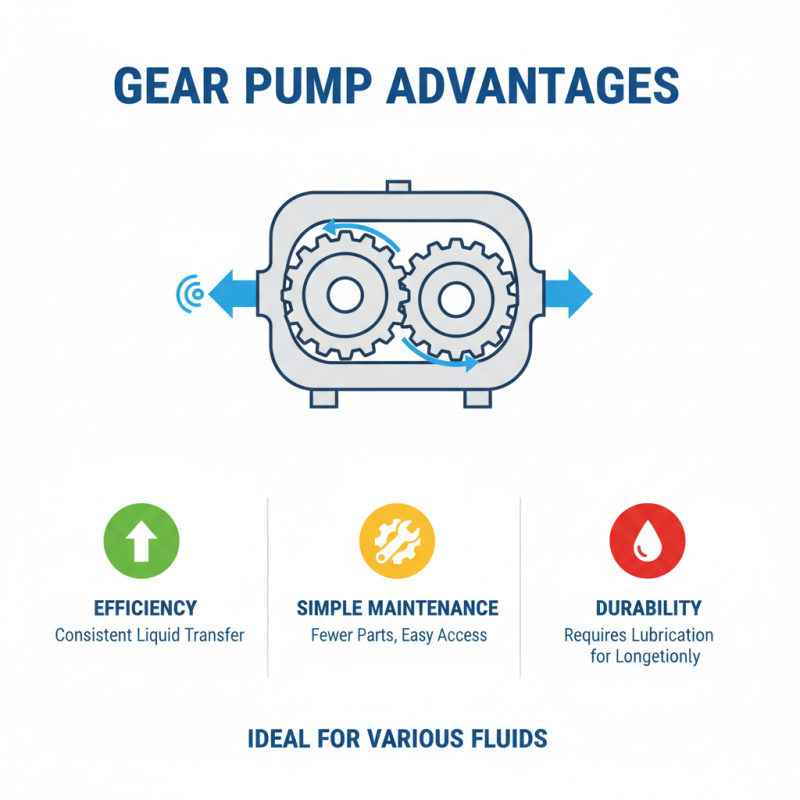

Gear pumps stand out for their efficiency in moving liquids. They operate using two or more gears that mesh together. This design creates a suction effect, drawing fluid into the pump. Their straightforward construction makes maintenance easier, but remember, they require proper lubrication.

One key feature of gear pumps is their ability to handle various viscosities. They can manage thick and thin fluids without losing performance. This versatility makes them ideal for many industries, from food processing to chemical manufacturing. Another benefit is their compact size. This allows for installation in tighter spaces, making them practical in many setups.

While gear pumps are robust, they do have limitations. They can be noisy, which may not be ideal in quiet environments. Additionally, if not monitored, they can run dry, leading to damage. Regular checks can prevent this, but it requires diligence. Embracing their pros and cons helps in making informed decisions.

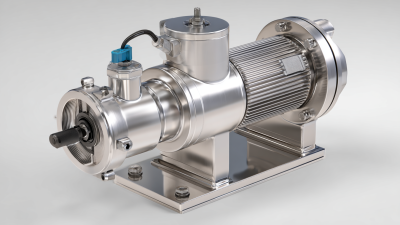

When selecting gear pumps, understanding specifications and features is crucial. These pumps are designed for transferring fluids efficiently. They come in various sizes and types, each suited for different applications. It’s essential to consider the viscosity of the fluid you plan to pump. Some pumps handle thicker liquids better than others.

Tips: Always check the maximum pressure rating of the pump. If it’s too low, you might face issues over time. Also, assess the noise level of the pump. Some operate quietly, while others can be quite loud, affecting workplace environment.

When reviewing gear pumps, pay attention to the material construction. Stainless steel versions resist corrosion better than others. Plastic models can suffice for non-corrosive liquids but may not be as durable. Think about maintenance needs, too. Some pumps require regular lubrication, while others are low-maintenance but might lack in performance during heavy usage.

Choosing the right gear pump involves balancing performance and maintenance. Appreciate both the strengths and weaknesses of each option you review. Avoid assuming that more expensive models always perform better.

This bar chart displays the flow rates of the top 10 gear pumps. The data illustrates the performance capabilities of each pump in liters per minute (L/min), helping users to compare and decide on the best gear pump for their needs.

Choosing the right gear pump for your needs is essential. Gear pumps come in various sizes and designs. Understanding your specific application is crucial. Consider the fluid type you will be pumping. Some fluids are thick while others are thin. Knowing the viscosity will help narrow down your options.

Pressure requirements are another important factor. High-pressure applications need robust pumps. Don't overlook the temperature of the fluids. Some pumps operate well in high heat, while others struggle. Analyze the environment where the pump will be used. Is it clean or dirty? Is there a risk of contamination?

It's easy to get overwhelmed by choices. Many people often forget to consider maintenance needs. Some pumps require more frequent upkeep than others. This can lead to unexpected downtime. Always factor in installation ease. A complex setup might not be worth the effort. Ultimately, take your time. Research and ask questions to make the right choice.