In the ever-evolving landscape of industrial applications, selecting the right pump skid packages is crucial for optimizing project efficiency and performance. According to John Smith, a renowned expert in the field of industrial pump systems, "Choosing the best pump skid package not only enhances operational productivity but also significantly reduces downtime and maintenance costs." This underscores the importance of making informed decisions when evaluating various options available in the market.

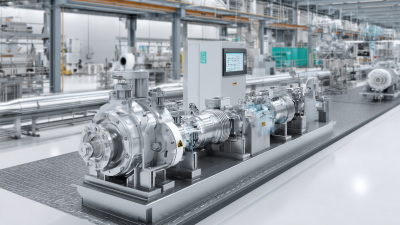

Pump skid packages are engineered solutions that combine pumps, motors, and supporting components into a single, compact unit, designed for easy transportation and installation. Their versatility makes them suitable for a wide array of applications, from water treatment to oil and gas projects. As industries increasingly shift towards integrated solutions, understanding the criteria for selecting the ideal package becomes imperative for engineers and project managers alike.

In this article, we will explore the key factors to consider when choosing pump skid packages for your specific project needs. By examining industry insights and expert recommendations, you will be better equipped to make decisions that align with both technical requirements and economic considerations, ensuring the success of your operations in a competitive market.

Pump skid packages are essential systems used in a variety of industrial applications, providing a compact and efficient solution for fluid handling. These packages typically consist of key components such as pumps, motors, piping, valves, and instrumentation, all mounted on a skid for easy transport and installation. According to the 2021 Global Pump Market report, the pump market is projected to grow at a CAGR of 5.2%, reaching approximately $72 billion by 2026, underlining the increasing demand for effective and reliable pumping solutions across multiple sectors.

When selecting a pump skid package, it is crucial to understand the specific requirements of your project. Key considerations include flow rate, pressure, and fluid type, as different applications will demand varying specifications from the pump. For instance, the American Society of Mechanical Engineers (ASME) recommends that pumps should be sized accurately to avoid inefficiencies and ensure optimal performance, which is vital given that an incorrectly sized pump can lead to a loss of 10-20% in energy efficiency. Additionally, understanding the materials used in the construction of the pump skid is important, as it can affect the system's durability and suitability for various operating conditions.

Overall, the choice of pump skid packages hinges on a thorough analysis of these components, aligning them with the operational demands of the intended application. Engaging with industry standards and leveraging data from reputable sources will aid in making informed decisions, ultimately leading to enhanced project outcomes.

This chart illustrates the importance of various criteria when selecting pump skid packages for project needs. Each criterion is rated on a scale from 1 to 10, helping project managers identify which factors are most critical to consider.

When selecting a pump skid package for your project, understanding the specific requirements in terms of flow rate, pressure, and fluid characteristics is crucial. Flow rate refers to the volume of fluid that must be moved within a given time frame. It is important to assess the peak demands of the application to ensure that the selected pump can maintain sufficient output without risking efficiency or causing damage. Accurate calculations based on the total dynamic head and the desired system performance will help determine an appropriate flow rate that meets project specifications.

Pressure is another key factor to consider, as it affects the entire system's performance and reliability. The pump must generate enough pressure to overcome system resistance while delivering the required flow rate. Factors such as elevation changes, pipeline size, and friction losses should be taken into account to ensure that the pump skid can function effectively within the operational parameters. It’s also essential to factor in the maximum and minimum pressure requirements to prevent operational failures.

Lastly, understanding fluid characteristics is vital in selecting a pump skid package. This involves assessing the type of fluid being pumped, including its viscosity, temperature, and chemical composition. Different fluids can have various impacts on pump material selection and performance. For example, corrosive substances may necessitate specialized materials to prevent degradation, while highly viscous fluids might require pumps designed for higher torque and lower speeds. By thoroughly evaluating these parameters, project managers can ensure that the chosen pump skid package is tailored to meet the specific needs of their application.

When selecting pump skid packages for your project needs, understanding key industry standards and regulations is crucial to ensure compliance, safety, and efficiency. Different industries may have specific guidelines that dictate design, construction, and operational parameters. For instance, the American National Standards Institute (ANSI) sets forth criteria that help in establishing performance metrics for pumps and ancillary equipment. Knowing these standards allows engineers to choose packages that align with both safety protocols and operational demands.

Additionally, factors like environmental regulations can influence the selection process. The Environmental Protection Agency (EPA) may impose restrictions that affect the design and materials used in pump skid systems, especially in industries dealing with hazardous substances. Understanding local compliance requirements can mitigate risks associated with environmental impact and regulatory penalties. A thorough assessment of these standards ensures that the chosen pump skid packages not only meet project specifications but also adhere to legal obligations, fostering a safer and more sustainable operational environment.

When embarking on a project that involves selecting a pump skid system, cost considerations play a critical role. Understanding the budgetary implications of pump skid packages is essential for effective project management. From initial procurement costs to long-term operational expenses, each factor contributes to the overall financial planning. It’s important to outline your budget clearly, taking into account not just the upfront costs of the package, but also installation, maintenance, and potential upgrades in the future.

**Tips:** Always allocate a contingency fund to cover unexpected costs that may arise during the installation or operation phases. Collaborate with suppliers to get detailed breakdowns of costs and inquire about long-term warranties and service options. This will help in evaluating the total cost of ownership and ensuring that the selected package meets both performance and financial expectations without compromising quality.

In addition to direct costs, consider indirect costs such as downtime and efficiency losses. Every project has a timeline, and delays can lead to increased expenses. Therefore, invest time in researching the reliability and efficiency of the pump skid systems. A well-chosen system will not only meet current project needs but will also provide operational savings in the long run, ensuring the investment yields the best possible return.

| Criteria | Description | Estimated Cost (USD) | Importance Level (1-5) |

|---|---|---|---|

| Pump Type | Select based on fluid characteristics and application | $10,000 - $30,000 | 5 |

| Material of Construction | Consider corrosion resistance and durability | $5,000 - $15,000 | 4 |

| Control System | Automation level and software requirements | $3,000 - $10,000 | 4 |

| Installation Costs | Labor and additional equipment for setup | $2,000 - $8,000 | 5 |

| Maintenance Requirements | Frequency and costs associated with upkeep | $1,000 - $5,000 annually | 3 |

| Warranty and Support | Coverage and reliability of assistance | $500 - $2,000 | 4 |

When selecting a pump skid package for your project, it is crucial to consider not only the initial specifications but also the long-term maintenance and support needed to ensure reliable performance. Regular maintenance checks can significantly extend the life of the equipment and enhance its efficiency. Understanding the maintenance requirements right from the outset can save time and costs in the future.

Tips for ensuring long-term performance include establishing a clear maintenance schedule that aligns with the manufacturer’s recommendations. This should involve routine inspections and servicing to check for wear and tear, fluid levels, and general operational status. Additionally, training personnel on proper operating procedures can prevent misuse and minimize the risk of damage.

Another critical aspect to consider is the availability of support services. Ensure that your pump skid package comes with accessible technical support and genuine spare parts. Having a reliable support network can make a significant difference when addressing unforeseen issues. Always ask about the warranty and service agreements to secure peace of mind for your project.