In the world of concrete placement, the line pump stands out as a crucial tool. John Smith, a renowned expert in the line pump industry, once said, "Efficiency and precision are key when using a line pump." This statement captures the essence of what a line pump can achieve on construction sites.

A line pump operates by using a series of hoses to transport concrete from the source to the desired location. Unlike larger boom pumps, line pumps are more portable and cost-effective. They can navigate tight spaces and deliver concrete to challenging areas. However, not all operators are trained equally. This can sometimes lead to mishaps.

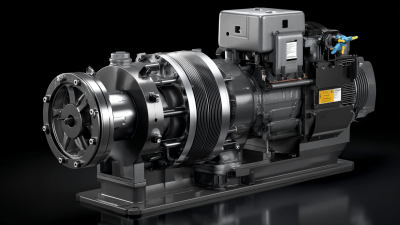

The mechanics of a line pump are simple yet require skill. The pump itself generates pressure to push the concrete through the line. Blockages can occur, and that's where experience truly matters. Proper maintenance is essential for optimal performance. In many places, operators lack a complete understanding of these machines. This gap can lead to inefficiencies and frustration on job sites. The line pump is powerful but requires respect and knowledge to operate effectively.

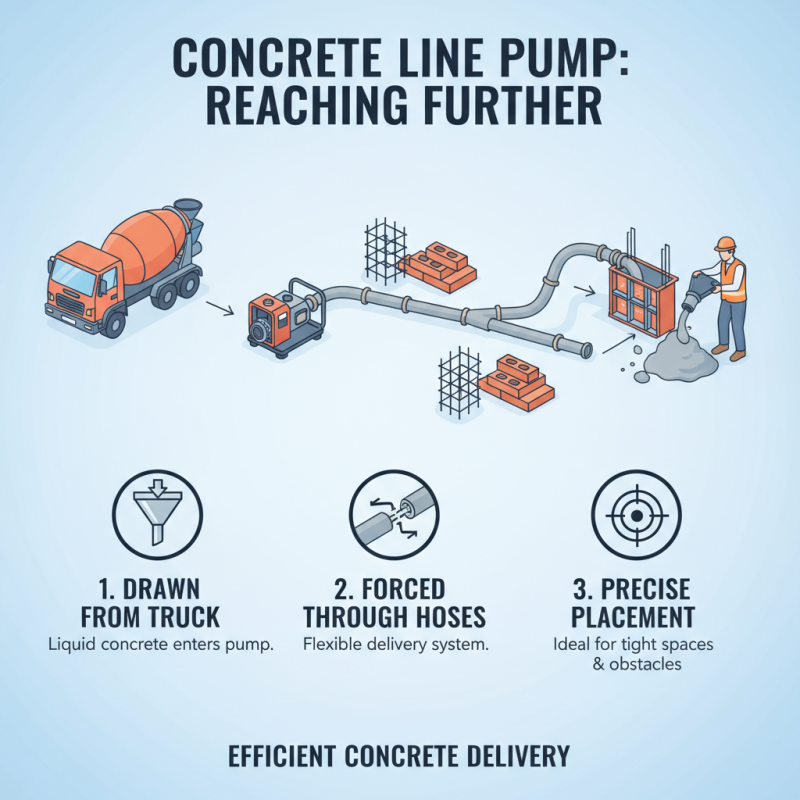

A line pump is a crucial tool in concrete construction. It allows for the efficient transport of concrete through hoses at various distances. Unlike boom pumps, line pumps use flexible hoses to direct the flow of concrete. This makes them ideal for smaller projects or tight spaces. The pump draws concrete from a mixer, pushing it through the hoses to the job site.

In operation, line pumps can deliver concrete at high pressure. This ensures a steady flow, even over obstacles. Workers can easily maneuver the hoses, ensuring the concrete reaches all necessary areas. However, managing the hoses can be challenging. Careless handling may cause blockages or spills. Proper training is essential for operators.

Tips: Ensure all hoses are clean before use. Check for any signs of wear or damage. This will help avoid leaks. Regular maintenance is key. Also, communicate clearly with your team to prevent mishaps. Keeping everyone on the same page will enhance safety and productivity. Remember, every project is unique. Adapt your approach as needed.

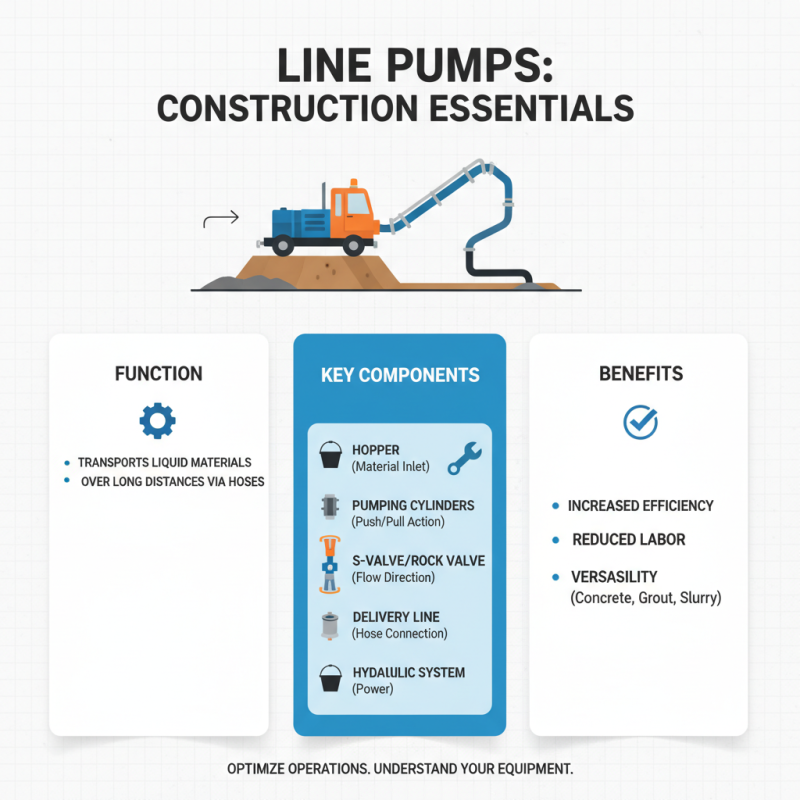

Line pumps are essential in the construction industry. They transport liquid materials over long distances through hoses. Understanding their components is key to ensuring efficient operation.

One critical element of a line pump is the pumping unit. This unit creates pressure to push materials through the hoses. According to industry reports, a well-maintained pumping unit can achieve up to 80% efficiency. However, wear and tear can diminish this efficiency, leading to costly delays. Regular inspection is necessary to avoid this downside.

Another vital component is the material hose. These hoses are designed to handle various materials, including concrete. Their flexibility allows for maneuvering around obstacles on job sites. However, improper handling can lead to damage or leaks. In construction, 20% of downtime is often attributed to hose failures. Regular training on proper hose management is essential since detailing instructions aren't always prioritized. This oversight can impact overall project timelines.

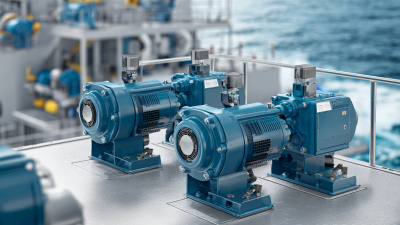

Line pumps are essential tools in construction and concrete delivery. They use a system of hoses and pipes to move liquid concrete from one location to another. This method is efficient for reaching tight spaces and navigating around obstacles. The process begins with the pump drawing concrete from a ready mix truck. The material is then forced through a series of hoses, making it easy to adjust the concrete's placement.

As concrete travels through the hoses, the pump's operation relies on hydraulic pressure. This pressure pushes the concrete quickly and smoothly. The pump operator can control the flow, ensuring that the mixture reaches the desired point. However, sometimes issues arise. Blockages can occur in the hoses if the concrete is too thick, leading to delays. Operators must stay alert to prevent such problems. Maintaining the pump and hoses is also a constant concern. Regular checks can prevent breakdowns during operation.

Operators should not only focus on the mechanics of the pump. Understanding the characteristics of the concrete being used is equally crucial. Not all mixtures flow the same way. A pump operator must adjust techniques based on the specific properties of the concrete. Each project can present unique challenges, requiring a thoughtful approach to ensure a successful pour.

Line pumps are vital in construction for efficiently transporting concrete. They use a series of hoses to convey the material from a truck to various locations. This method is ideal for pouring concrete in tight spaces. Many construction sites benefit from this setup. Reports indicate that nearly 30% of construction projects now leverage line pumps for their flexibility.

In urban areas, line pumps help reduce noise. They allow for better maneuverability compared to traditional boom pumps. Some construction teams report less disruption to nearby activities. However, challenges remain. If hoses are not properly managed, it can lead to concrete spills. This can slow down operations and increase costs.

Line pumps are particularly useful for high-rise buildings. Data shows that these pumps are crucial for projects exceeding five stories. This type of pumping often requires careful planning. If not done correctly, it might compromise the integrity of the mix. Many professionals are still learning to optimize this process, making it an ongoing area for improvement.

Line pumps have become a popular choice for construction projects. They offer unique advantages that set them apart from other pumping methods. One major benefit is their flexibility. They can transport concrete to hard-to-reach locations. This is especially useful in urban areas where space is limited. Line pumps use hoses, allowing precise delivery.

Another advantage is efficiency. Line pumps operate quickly, minimizing downtime. This helps speed up pouring processes. On-site labor can be reduced. Fewer workers may be needed to manage the setup. Plus, the setup is generally simpler than with boom pumps.

However, manning a line pump requires some skill. Operators should be trained to handle the hoses effectively. Mismanagement can lead to blockages. These can delay projects. Reflecting on the usage of line pumps highlights the balance between automation and skilled labor. The goal should always be to improve productivity while ensuring safety.

| Feature | Line Pump | Other Pumping Methods |

|---|---|---|

| Mobility | High (can be easily moved on site) | Varies (depends on equipment) |

| Pumping Distance | Long (can pump over 1000 feet) | Short to Moderate |

| Setup Time | Quick (usually under 1 hour) | Longer (can take several hours) |

| Concrete Types | Suitable for various types (including low slump) | May require specific types |

| Cost Efficiency | Generally cost-effective | Higher operational costs |

| Labor Requirement | Less labor-intensive | More manpower needed |

| Maintenance | Lower maintenance requirements | Higher maintenance requirements |