Industrial pumping solutions play a critical role in enhancing operational efficiency across various industries. These systems are designed to transport fluids effectively, ensuring that processes run smoothly and minimizing downtime. As noted by industry expert Dr. Emily Carter, "The right choice of industrial pumping solutions can significantly reduce operational costs and increase productivity." This highlights the importance of selecting appropriate pumping technologies tailored to specific operational needs.

In a world where efficiency is paramount, understanding the intricacies of industrial pumping solutions becomes essential for businesses aiming for growth and sustainability. From manufacturing to energy production, these solutions not only facilitate the movement of liquids but also contribute to enhanced safety and environmental compliance. The integration of advanced pumping systems can lead to substantial operational improvements, enabling companies to maintain competitiveness in an ever-evolving market.

As we delve into the benefits of industrial pumping solutions, it is vital to explore how these systems can be optimized for various applications, driving innovation and ensuring that industries can meet their unique challenges head-on. By leveraging the latest technologies and expert insights, organizations can harness the power of efficient pumping solutions, paving the way for a more productive future.

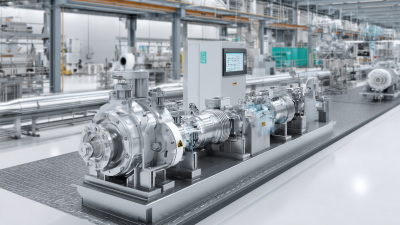

Industrial pumping solutions are essential systems designed to move fluids and slurries across various sectors, from manufacturing to wastewater treatment. These solutions typically comprise several key components, including pumps, motors, control systems, and piping. The pumps are the heart of the system, classified mainly into centrifugal and positive displacement types. Centrifugal pumps are ideal for low-viscosity fluids, while positive displacement pumps handle thicker liquids. Selecting the right pump type is crucial to ensure operational efficiency and cost-effectiveness.

In addition to pumps, motors play a vital role in driving the systems, providing the necessary power to facilitate fluid movement. Control systems are incorporated to monitor and regulate the pump operations, ensuring optimal performance and safety. Piping and fittings connect these components, forming a seamless network for fluid transport. By integrating these components, industrial pumping solutions enhance productivity, reduce downtime, and facilitate maintenance. The overall design tailored to specific applications can significantly influence the efficiency of operations, making these systems indispensable in modern industrial workflows.

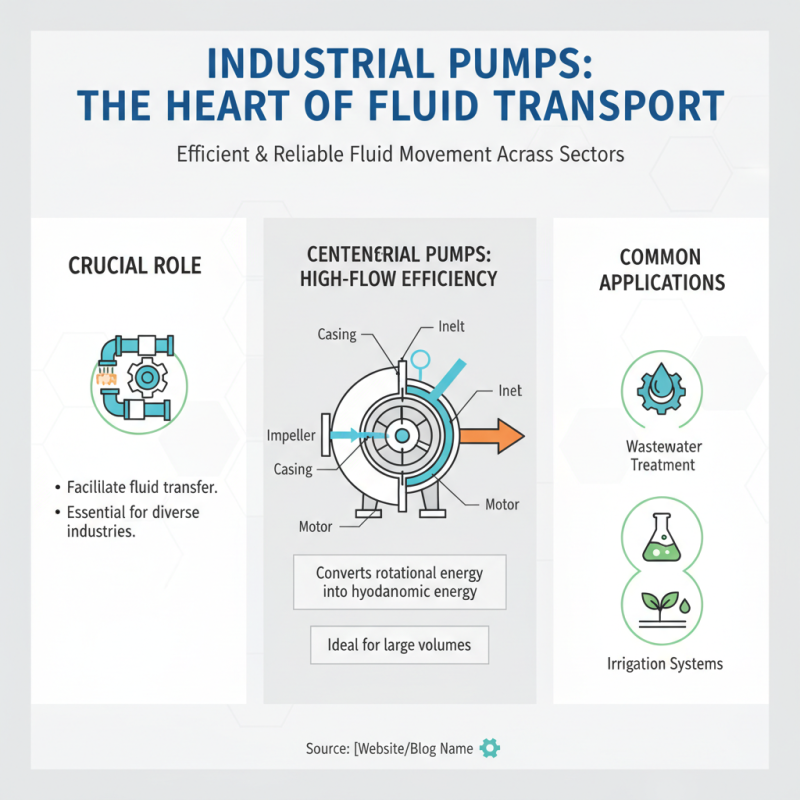

Industrial pumps play a crucial role in various sectors, facilitating the movement of fluids in an efficient and reliable manner. There are several types of industrial pumps designed for specific applications, each utilizing different technologies to meet the diverse needs of operations. Centrifugal pumps, for instance, are widely used for their ability to handle large volumes of liquid with high flow rates. They operate on the principle of converting rotational energy into hydrodynamic energy, making them ideal for wastewater treatment, chemical processing, and irrigation systems.

In contrast, positive displacement pumps are designed to move fluids by trapping a fixed amount and forcing it into the discharge pipe. This makes them particularly effective for handling viscous fluids and slurries, commonly used in the oil and gas industry, food processing, and pharmaceuticals. Selecting the appropriate pump type not only enhances operational efficiency but also increases the longevity of the equipment and reduces maintenance costs. Understanding these different technologies can empower operators to make informed decisions that ultimately optimize productivity and resource management.

Industrial pumping solutions play a crucial role in enhancing operational efficiency across various industries. By utilizing advanced pumping technologies, businesses are able to ensure smooth and consistent fluid transfer, which is fundamental to maintaining production schedules. Efficient pumping systems minimize downtime caused by equipment failures or maintenance issues, allowing operations to run seamlessly. Furthermore, by optimizing pump performance, companies can effectively manage their resources—reducing energy consumption and minimizing wear and tear on machinery.

Cost reduction is another significant advantage of implementing industrial pumping solutions. By improving fluid handling processes, organizations can significantly lower utility costs associated with energy consumption. Additionally, advanced pumping systems often come equipped with automated controls and monitoring capabilities that enable predictive maintenance, identifying potential problems before they escalate into costly repairs. This proactive approach not only extends the lifespan of the equipment but also helps in allocating budgets more effectively, allowing businesses to redirect savings towards growth initiatives. Overall, the strategic adoption of industrial pumping solutions is key to achieving both efficiency and financial sustainability in operations.

The industrial pumping solutions market has shown significant growth over the past few years, driven by advancements in technology and increasing demand across various sectors, including oil and gas, water and wastewater management, and chemical processing. Recent statistics indicate that the global pumping solutions market is projected to reach several billion dollars by the end of this decade, highlighting an upward trend in both market size and consumer investments. The incorporation of smart technologies and energy-efficient designs has played a crucial role in attracting businesses seeking to optimize their operations and reduce costs.

Moreover, the growth trends reflect a shift towards sustainable practices, with many companies prioritizing environmentally friendly pumping solutions. Industry reports demonstrate that sectors such as renewable energy and industrial automation are increasingly reliant on innovative pumping technologies to enhance their operational efficiency. As industries continue to evolve, the demand for reliable and efficient pumping solutions remains strong, ensuring a robust market outlook that aligns with the global emphasis on sustainability and operational excellence.

In modern industrial operations, the implementation of effective pumping solutions can lead to significant operational benefits, as evidenced by numerous case studies across various sectors. For instance, a recent report from the American Society of Mechanical Engineers highlighted that industries utilizing advanced pumping technology experienced a remarkable 20% increase in efficiency. This improvement was primarily observed in the manufacturing and chemical processing sectors, where the optimization of fluid movement is critical. By employing variable speed drives and precision-engineered pumps, companies not only reduced energy consumption but also minimized maintenance costs, resulting in substantial savings.

A case study within the mining industry further illustrates this advantage. A major mining operation adopted a new pumping solution that integrated smart monitoring systems, allowing real-time data collection and analysis. As a result, the operation was able to reduce unplanned downtime by approximately 30%, leading to enhanced production rates. Industry reports indicate that effective pump management can contribute to a remarkable decrease in operational disruptions, ultimately improving overall productivity. Such data-driven decisions underscore the value of implementing robust industrial pumping solutions in achieving operational excellence and maximizing resource utilization.

| Case Study | Industry | Problem | Solution Implemented | Results Achieved |

|---|---|---|---|---|

| Case Study A | Chemical Processing | Frequent pump failures | Upgraded to high-efficiency pumps | Reduced downtime by 30% |

| Case Study B | Water Treatment | Inefficient water flow | Implemented variable frequency drives | Increased flow rate by 25% |

| Case Study C | Oil & Gas | High energy costs | Adopted energy-efficient pump systems | Saved 20% on energy consumption |

| Case Study D | Food Processing | Contamination risks | Invested in sanitary pumps | Eliminated contamination incidents |

| Case Study E | Mining | Water management issues | Installed automatic monitoring systems | Optimized water usage by 40% |