Centrifugal pump parts play a crucial role in various industries. Understanding these components can enhance performance and efficiency. Each part contributes to the overall functionality of a centrifugal pump.

The impeller is one of the most vital components. It helps move fluid through the pump. Another key part is the casing, which houses the impeller and ensures fluid doesn’t escape. The shaft also deserves attention, as it connects the impeller to the motor.

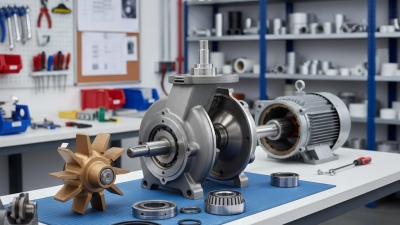

While these parts seem straightforward, they wear out over time. Regular maintenance is essential. Ignoring this can lead to costly repairs and downtime. Understanding centrifugal pump parts can empower operators to make informed decisions in their maintenance strategies.

Centrifugal pumps are vital in many industries. They move fluids by converting rotational energy into hydraulic energy. Understanding their parts is crucial for optimal performance. Every component plays a role in the pump's efficiency.

The impeller is one key element. It drives fluid through the pump. Studies show that almost 40% of pump failures relate to impeller issues. Regular inspection can prevent costly downtime. Another essential part is the volute. It helps direct the flow and reduces turbulence. Neglecting this part can lead to inefficiencies.

Seals are often overlooked, yet they are critical for preventing leaks. A 2023 report indicated that leaking pumps waste millions in resources annually. Maintenance of seals is not just important; it’s necessary. Casing materials also matter. They must withstand the fluid’s temperature and pressure. Poor choices can result in pump failures. Understanding these parts can lead to better decisions. It also highlights the need for constant education in pump technology.

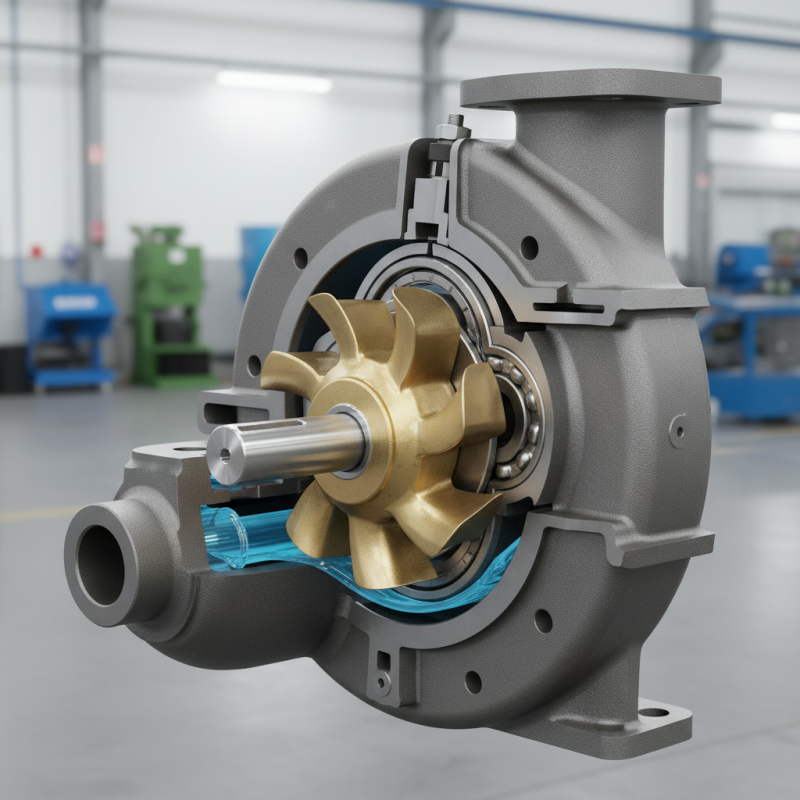

Centrifugal pumps are vital in many industries, making their components crucial. The impeller is the heart of the pump. It transfers energy to the fluid, causing it to flow. The design of the impeller affects efficiency significantly. A poorly designed impeller may lead to cavitation, reducing performance.

The casing encloses the impeller. It plays a role in directing fluid flow. A tight fit is necessary to minimize leaks, yet, too tight can cause excessive wear. Another key component is the shaft. It connects the motor to the impeller. A weak shaft can fail under high stress. This can halt operations and increase costs.

Seals prevent fluid leakage. They are often overlooked but are essential. A worn seal can result in fluid loss and pump failure. Lastly, the bearings support the shaft. Poor lubrication can lead to premature wear. Understanding these components is vital for effective maintenance. Each part has a specific role and neglecting any can lead to unexpected downtime.

| Component | Function | Material | Maintenance Tips |

|---|---|---|---|

| Impeller | Converts rotational energy into fluid velocity | Cast Iron, Stainless Steel | Inspect for wear, replace if damaged |

| Volute | Houses the impeller and directs fluid flow | Cast Iron, Plastic | Check for cracks and corrosion |

| Suction Pipe | Allows fluid entry into the pump | PVC, Stainless Steel | Ensure no leaks and clear blockages |

| Discharge Pipe | Transports fluid out of the pump | PVC, Stainless Steel | Check for leaks and proper alignment |

| Mechanical Seal | Prevents leakage between rotating and stationary parts | Carbon, Ceramics | Inspect regularly for wear and replace as needed |

| Bearing | Supports rotating elements and reduces friction | Steel, Bronze | Lubricate regularly, check for noise |

| Motor | Provides the necessary power for pump operation | Aluminum, Steel | Ensure correct voltage and check for overheating |

| Strainer | Prevents debris from entering the pump | Stainless Steel, Plastic | Clean regularly to avoid clogging |

| Control Valve | Regulates the flow and pressure of the fluid | Brass, Plastic | Inspect for leaks and operability |

| Pump Casing | Encases and protects the internal components | Cast Iron, Composite Materials | Check for structural integrity |

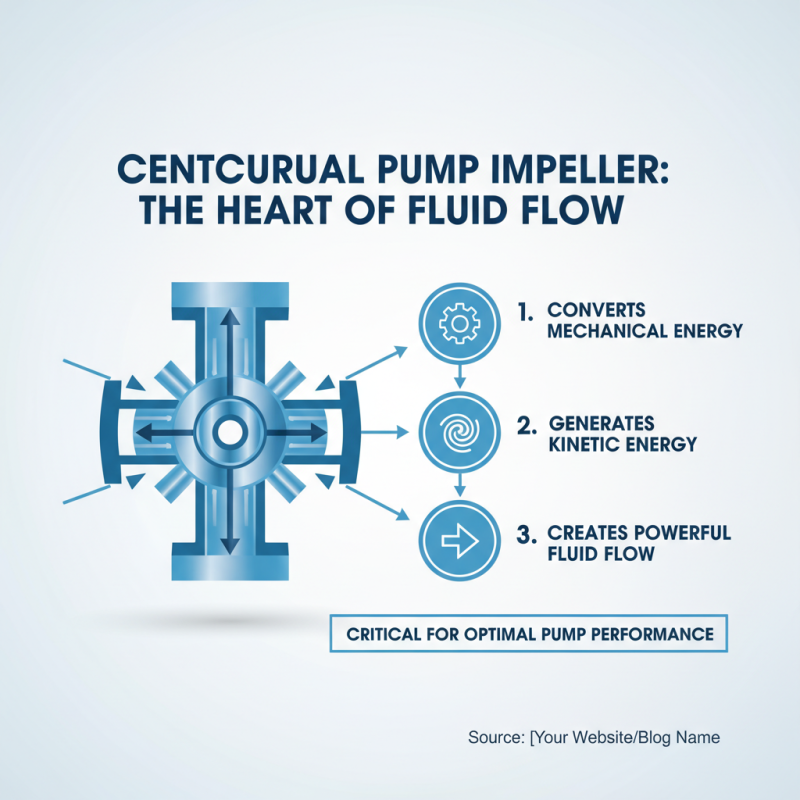

The impeller is critical to centrifugal pump performance. It fosters fluid movement through the pump system. This component converts mechanical energy into kinetic energy. A well-designed impeller creates a strong, fast fluid flow.

When selecting impellers, consider size and shape. Each design affects efficiency. A wider impeller can move more fluid, but often at lower pressure. Conversely, a narrow impeller increases pressure but reduces flow. Finding the right balance is crucial, yet many decisions rely on trial and error.

Pump operators sometimes overlook wear and tear on impellers. This can lead to decreased efficiency. Routine checks can help identify issues early. Observing inlet and outlet flow rates will reveal performance problems. Impeller performance directly influences the overall effectiveness of the pump system. Understanding this relationship is vital for long-term operation.

Centrifugal pump casings play a crucial role in optimizing performance and efficiency. Studies indicate that casings account for about 15-20% of the total pump efficiency. They house the impeller and direct fluid flow, minimizing turbulence and energy loss. A well-designed casing can significantly enhance the hydrodynamic performance of the pump.

The shape and material of the casing also matter. Materials like cast iron or stainless steel are often used for their durability. Recent industry reports highlight that the right casing design can increase overall efficiency by up to 10%. However, not all designs are perfect. Inefficient casings can lead to cavitation, which damages the pump over time. This issue highlights the need for continuous improvement in engineering designs.

Moreover, maintenance is essential. A worn or corroded casing impacts performance. Regular checks can reveal hidden inefficiencies. Up to 30% of pumps face performance issues due to casing neglect, according to industry surveys. Engineers must balance between cost-effectiveness and optimal design to ensure longevity and reliability.

This chart illustrates the importance rating of essential centrifugal pump parts, with casing and impeller at the top due to their critical roles in enhancing pump efficiency.

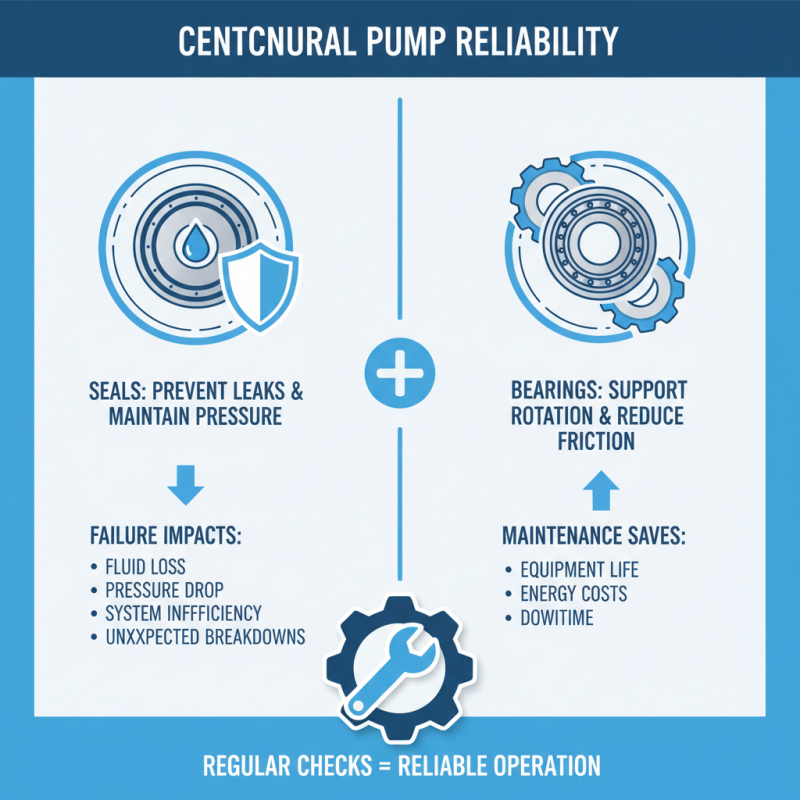

In centrifugal pump systems, seals and bearings play a crucial role in ensuring reliability. Seals prevent fluid leaks, maintaining system pressure and efficiency. When seals fail, it can lead to significant losses. A simple drop in pressure can affect the entire system. Regularly checking seals for wear can prevent unexpected breakdowns.

Bearings support rotating components, providing smooth operation. They endure high loads and can wear out over time. Lubrication is essential, yet it’s often overlooked. Insufficient lubrication can lead to overheating and eventual failure. For optimal performance, maintaining bearings should be a priority.

Many operators may forget these components during maintenance checks. Ignoring them can cause serious issues. It's important to develop a habit of assessing both seals and bearings regularly. This attention to detail can enhance the durability and efficiency of centrifugal pump systems. Each small oversight can lead to larger problems down the line. Be proactive rather than reactive.