Centrifugal pumps play a crucial role in various industries, including water treatment, oil and gas, and chemical processing. Understanding the essential centrifugal pump parts is vital for optimal performance and longevity. According to a recent market report, the global centrifugal pump market is projected to reach over $40 billion by 2027, signifying its importance in industrial applications.

Key components such as impellers, casing, and seals directly impact efficiency. The impeller determines the flow rate, while the casing affects pressure. However, many operators overlook the significance of regular maintenance and inspection of these centrifugal pump parts. Research indicates that improper maintenance can lead to a 20% drop in efficiency over time, highlighting the need for vigilance.

Each part's function not only contributes to the pump's overall performance but also plays a role in operational safety. Yet, many professionals often neglect to train staff on these critical components. This oversight can result in costly downtime and repairs. It is essential to prioritize education on centrifugal pump parts to ensure maximum reliability and productivity in industrial processes.

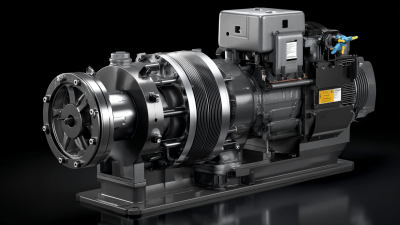

Impellers are critical components in centrifugal pumps. They convert rotational energy into kinetic energy. This action generates flow and pressure in the fluid. According to industry reports, impellers account for about 50%-60% of the pump's overall efficiency. This highlights their importance in various applications.

The design of an impeller significantly affects pump performance. A well-designed impeller can enhance flow rates and reduce energy consumption. However, imperfections in design often lead to cavitation and reduced lifespan. A recent study noted that over 30% of pumps fail prematurely due to impeller issues. This points to the need for better engineering and testing during manufacturing.

Materials used in impeller manufacturing also play a role. Common materials include stainless steel and plastic. Each material offers distinct advantages and challenges. For example, while stainless steel is durable, it may corrode when exposed to certain fluids. In contrast, plastic impellers are lighter but may suffer from wear. Understanding these trade-offs is essential for selecting the right impeller design.

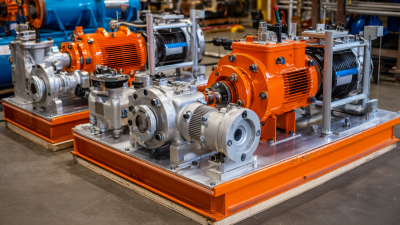

Volutes play a critical role in the design and functionality of centrifugal pumps. They are the spiral components that guide fluid flow efficiently. Without a well-designed volute, the performance of a pump can significantly decline. The shape and size of a volute impact how effectively the pump can transfer energy to the fluid. This can lead to turbulence and inefficient flow.

Improper volute design can create unwanted pressure fluctuations. These issues may cause both wear on pump parts and reduce overall efficiency. Many may overlook this aspect in early design phases. It often leads to performance issues down the line. A volute should not be an afterthought; it must be integrated thoughtfully into the pump design.

Understanding the importance of volutes can enhance pump performance. Engineers must pay attention to the geometry and material used. This can make a real difference in operational longevity and maintenance needs. It’s essential to test different designs for optimal performance. Continuous reflection on these details helps ensure pumps run smoothly. The volute remains a vital aspect that demands careful consideration.

Centrifugal pumps are vital in various industries. Seals and bearings play a crucial role in their efficiency. Seals prevent leaks. They ensure that the fluid remains contained within the pump. A leaking pump can lead to costly downtime. According to a report from the Hydraulic Institute, seal failures account for nearly 30% of pump maintenance costs.

Bearings support the rotor, allowing it to spin smoothly. They minimize friction, enhancing the pump's lifespan. The right bearing selection can impact performance significantly. In fact, a study published in the Journal of Mechanical Engineering revealed that incorrect bearing choices could reduce efficiency by 15%. Many operators overlook these details, which may lead to mechanical failures.

The ignored potential of proper maintenance and regular checks can lead to severe issues later. Over time, seals wear out and bearings may become misaligned. Simple inspections can prevent major failures. However, many in the industry still underestimate this process. A proactive approach to maintaining seals and bearings can save time and costs in the long run.

| Part | Function | Material | Common Issues | Maintenance Tips |

|---|---|---|---|---|

| Mechanical Seal | Prevents leakage of fluid | Ceramic, Carbon | Leakage, Wear | Regular inspection, Replace when worn |

| Bearing | Supports rotating shaft | Steel, Bronze | Overheating, Noise | Lubrication, Replace if noisy |

| Impeller | Moves fluid through the pump | Cast Iron, Stainless Steel | Corrosion, Cavitation | Check for damage, Clean regularly |

| Volute | Converts velocity to pressure | Cast Iron, Composite | Wear, Erosion | Monitor for wear, Repair cracks |

| Suction Strainer | Prevents debris from entering | Stainless Steel, Plastic | Clogging, Damage | Regular cleaning, Replace when damaged |

Centrifugal pumps are vital in various industrial applications. Their performance largely depends on the casing type. This casing shapes the flow path and affects efficiency. According to the Hydraulic Institute, about 54% of pump energy loss is due to hydraulic inefficiencies linked to casing design. Choosing the right casing is critical for optimal performance.

Different casing types exist, each influencing performance differently. Open casings lead to lower efficiency but are easier to clean. Closed casings provide higher efficiency and better protection against debris. A study by the American Society of Mechanical Engineers noted that closed casings can improve overall performance by 15% over open types. However, this comes at the cost of maintenance complexity.

Tips: Always assess your system requirements. Select a casing type that aligns with your efficiency goals. Consider operational conditions, like fluid type and temperature. Regular maintenance can prevent unforeseen failures. Ignoring casing wear can lead to reduced efficiency.

Remember, even small changes in casing design can yield significant impacts. Testing different configurations may uncover hidden efficiencies. Stay informed about trends in pump technology. This knowledge helps avoid costly mistakes in the long run.

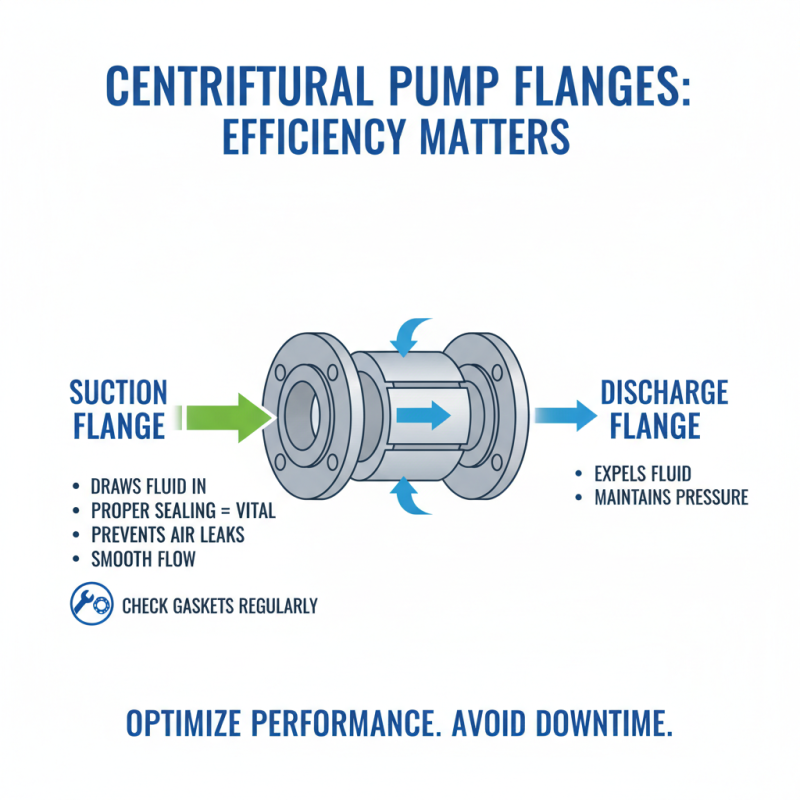

Suction and discharge flanges play a critical role in centrifugal pump efficiency. The suction flanges draw fluid into the pump. Proper sealing here is vital. Any leaks can lead to air ingress, disrupting the flow. Make sure the flanges are correctly assembled. Inspect gaskets regularly to avoid unnecessary breakdowns.

Discharge flanges, on the other hand, direct the pumped fluid out. They need to handle high pressure. A poorly designed discharge system can create back pressure, impacting performance. Think about how these parts connect to the rest of your piping system. It’s important to match flange sizes properly.

Regular maintenance is often overlooked. Check for corrosion or wear on both flanges. Sometimes, the problem is not immediately visible. You might notice slow performance over time. It’s crucial to be proactive about these components. Proper maintenance can save costs in the long run.