Choosing the right self priming pump for your needs can significantly impact efficiency and performance in various applications. According to John Doe, a leading expert in the pumping industry, "Selecting the correct self priming pump is crucial, as it can save time and reduce long-term operational costs." With the plethora of options available in the market today, understanding the fundamentals of self priming pumps becomes essential for both novices and seasoned professionals.

Self priming pumps are designed to efficiently handle liquids, including those mixed with air or vapor, making them a preferred choice in numerous settings such as agriculture, construction, and wastewater management. The versatility and reliability of these pumps stem from their unique ability to prim from dry conditions without the need for manual intervention. As you navigate the various specifications and features, it is vital to consider the specific requirements of your application to ensure optimal performance.

In this guide, we will explore key factors to evaluate when selecting the right self priming pump for your specific requirements. Whether it's flow rate, material compatibility, or intended application, making an informed decision can lead to enhanced productivity and lower maintenance costs in the long run. With expert insights and practical advice, you will be poised to find the most suitable self priming pump for your needs.

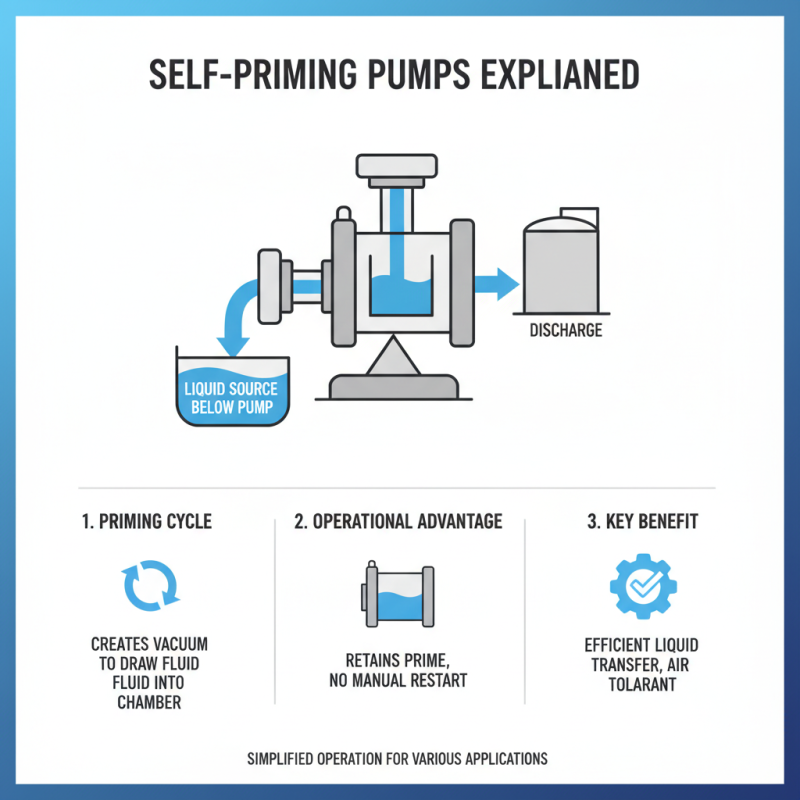

Self-priming pumps are engineered to efficiently move liquids, often in environments where introducing air into the system is unavoidable. Understanding their basic mechanics is crucial for selecting the right pump for your application. The self-priming mechanism involves creating a vacuum that enables the pump to draw fluid into the chamber from a source below the pump level. It retains the necessary prime even after stopping, which simplifies the operation and reduces the need for manual priming.

The operation of self-priming pumps typically employs a unique impeller design that helps in moving the liquid quickly into the pump housing. Upon activation, the pump expels the air, creating a partial vacuum that allows ambient fluid to fill the pump chamber. This feature is particularly beneficial in various applications, such as construction, agriculture, and waste management, where suction lift capabilities and efficiency are vital. Optimal selection involves considering factors such as the pump's lift capacity, flow rate, and the fluid characteristics to ensure longevity and performance in your specific applications.

When selecting a self-priming pump for your specific needs and applications, several key factors should be considered to ensure optimal performance and efficiency. First, it's crucial to evaluate the fluid characteristics that the pump will handle. This includes understanding the viscosity, temperature, and chemical composition of the fluid. Self-priming pumps are designed to handle a range of liquids, but certain conditions such as high viscosity or corrosive substances may require specialized materials or designs to prevent damage and ensure effective operation.

Another important factor is the required flow rate and head. Calculating the desired flow rate helps in selecting a pump that will deliver the necessary volume under the operating conditions. Additionally, considering the total dynamic head, which includes vertical lift and resistance from piping, is essential for ensuring that the pump can perform effectively in your application. Also, take note of the suction lift capabilities, as self-priming pumps have specific limits on how far they can draw fluid from a source. Understanding these parameters will aid in choosing a pump that meets the performance specifications for your project.

When selecting a self-priming pump, understanding flow rates and lift heights is crucial for ensuring optimal performance for your specific applications. Flow rate refers to the volume of fluid that the pump can move per unit of time, typically measured in gallons per minute (GPM) or liters per second (L/s). According to the Hydraulic Institute, the required flow rate for any given application is determined by the system's demands, including the required pressure, the type of fluid, and the specific use case. For instance, agricultural irrigation systems often need higher flow rates to efficiently distribute water across vast areas, whereas smaller systems, like a home water supply, may operate effectively at lower rates.

Lift height, on the other hand, is a measure of how high a pump can move a liquid vertically against gravitational forces. This parameter is critical in applications such as sewage pumping or water transfer from low to high elevations. The American Society of Mechanical Engineers (ASME) states that the total dynamic head (TDH) encompasses not only lift height but also pressure losses due to friction in the system. It is essential to calculate TDH accurately to select a self-priming pump that can handle the expected demands with a safety margin. Misjudging either flow rate or lift height can result in inadequate performance or excessive energy consumption, highlighting the importance of accurate assessments before making a selection.

When selecting a self-priming pump, the materials and design choices are crucial for ensuring durability across different environments. Pumps made from corrosion-resistant materials, such as stainless steel or high-grade plastics, can withstand exposure to harsh chemicals and abrasive materials. This is particularly important in applications like wastewater management or chemical processing, where exposure to challenging substances is inevitable. Additionally, consider the design features that enhance durability, such as reinforced casings and protective coatings that resist wear and tear.

Tips: Always assess the specific environment where the pump will be used. For instance, if the pump is going to be exposed to extreme temperatures, opt for materials rated for such conditions. Furthermore, ensure that the seals and closures of the pump are designed to prevent leaks, as this will contribute significantly to its longevity.

Another critical aspect is the pump's operating conditions, where factors like vibration and cyclical load can affect performance. Choosing a pump with an ergonomic design and built-in shock absorption mechanisms can help mitigate these effects, thereby extending the lifespan of the pump. Ensure that all components, from the impeller to the housing, are engineered for the intended application to ensure efficiency and reliability.

Tips: Regular maintenance of your pump will also improve its durability. Implement a routine check for wear and tear, and replace any parts that show signs of deterioration to keep your pump running optimally in its specific environment.

Self-priming pumps are essential in various industries, offering ease of use and efficiency in transferring fluids. These pumps are specifically designed to handle applications with low fluid levels and can effectively re-prime after losing prime. Common applications include agricultural irrigation, wastewater management, and chemical processing, where reliable pumping solutions are vital. According to the Global Self-Priming Pumps Market report, the demand for these pumps is projected to grow at a compound annual growth rate (CAGR) of 4.6% between 2021 and 2028, driven by the need for efficient fluid handling in emerging markets.

When selecting a self-priming pump, it’s important to consider industry standards such as the American National Standards Institute (ANSI) guidelines, which speak to the pump's performance and safety specifications. Additionally, flow rates, suction lift, and the specific characteristics of the fluids being handled—such as viscosity and corrosiveness—play a crucial role in the selection process. For example, in the food processing industry, pumps must meet hygiene and safety standards, ensuring that they can handle sensitive fluids without contamination. Understanding these applications and standards will help users make informed decisions that align with their operational requirements and maintain compliance with regulatory frameworks.

| Application | Industry | Flow Rate (GPM) | Max Head (Feet) | Power Source |

|---|---|---|---|---|

| Agricultural Irrigation | Agriculture | 20 | 150 | Diesel |

| Wastewater Management | Municipal | 50 | 100 | Electric |

| Construction Dewatering | Construction | 40 | 80 | Gasoline |

| Fire Fighting | Emergency Services | 250 | 300 | Diesel |

| Marine Applications | Marine | 15 | 60 | Electric |