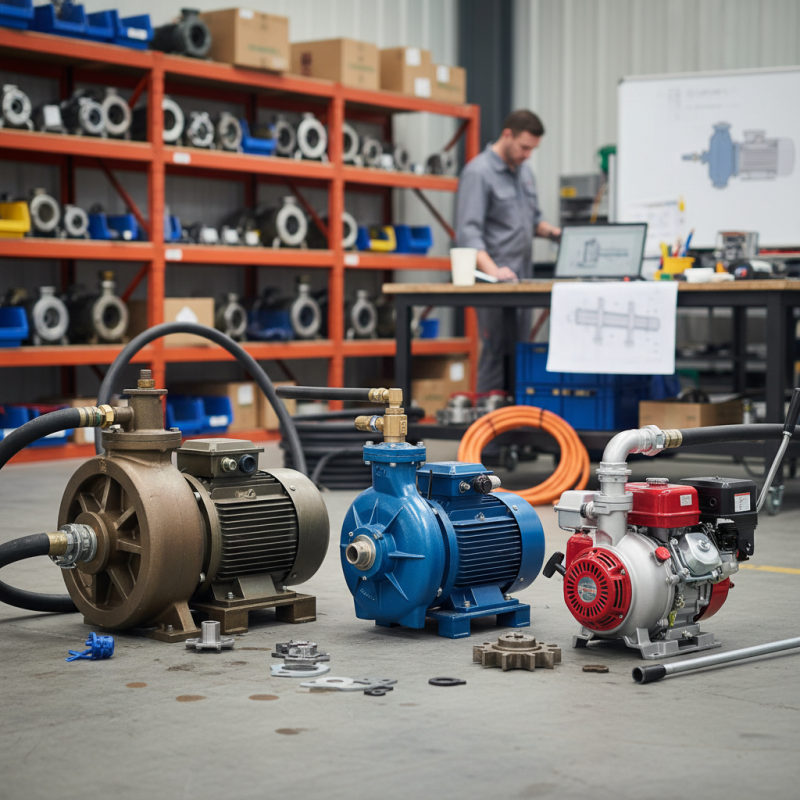

Choosing the right self priming pump can be challenging. With a variety of options available, it's crucial to understand your specific needs. John Smith, a leading expert in the pump industry, once stated, "Selecting the correct self priming pump can greatly enhance efficiency and performance."

self priming pumps are designed to create their own suction, making them ideal for various applications. Whether you need one for irrigation, industrial use, or residential projects, factors like flow rate, power source, and materials are important. Also, not all self priming pumps hold up under different conditions.

Many users overlook maintenance requirements. A self priming pump may work well initially but can falter without proper care. It's a reminder that the right choice does not guarantee long-term success. Evaluating your investment and understanding the pump's limits is essential. Take time to research and consider how a self priming pump fits into your specific situation.

Self-priming pumps are versatile and efficient tools commonly used in various applications. They are designed to lift liquids and create a vacuum, allowing them to self-prime. This means they can pump water even when the intake line is not filled. Understanding their applications is crucial for selecting the right one.

These pumps are often used in agricultural irrigation, construction sites, and wastewater treatment. Their ability to handle air and liquid mixtures makes them ideal for situations where priming a conventional pump is challenging. The pumping action stays consistent, and they can run dry for a short period without damage.

When choosing a self-priming pump, consider the type of liquid you'll be moving. If it contains solids, ensure your pump can handle that. The flow rate and total head lift are also essential.

Tips: Always check the manufacturer's specifications. Make sure the pump meets your specific needs. Watch out for signs of wear, as they can affect performance. Regular maintenance can't be overlooked. It extends the lifespan and efficiency of the pump.

| Pump Type | Flow Rate (GPM) | Max Lift (Feet) | Power Source | Common Applications |

|---|---|---|---|---|

| Diaphragm Pump | 10-15 | 25 | Electric | Water Transfer, Irrigation |

| Centrifugal Pump | 20-30 | 20 | Gasoline | Construction, Dewatering |

| Gear Pump | 5-10 | 15 | Electric | Oil and Chemical Handling |

| Self-Priming Trash Pump | 30-50 | 25 | Gasoline | Flood Control, Waste Water Management |

When selecting a self-priming pump, it’s essential to understand key factors that affect its performance. Flow rate is crucial. Many applications require pumps that can handle specific flow demands. Industry reports indicate that pumps with a flow rate between 10 to 100 gallons per minute are commonly used in agriculture and construction. Understanding your specific needs can help prevent inefficient choices.

Another important factor is suction lift capability. A pump's ability to draw water from a specific depth can affect system efficiency. Typically, self-priming pumps can achieve suction lifts of up to 25 feet. Choosing a pump that meets your specific lift requirements ensures smoother operation and reduces maintenance frequency.

**Tip:** Always measure the height of the water source before purchasing a pump. This prevents mismatches in performance.

Maintenance considerations should not be overlooked. Self-priming pumps require regular checks to avoid potential failures. The majority of pump breakdowns stem from cavitation issues. This is prevalent when the pump operates beyond its capacity. Understanding these limitations can help maintain effective operation over time.

**Tip:** Schedule regular maintenance and inspections to extend the life of your pump.

When selecting a self-priming pump, understanding the various types is crucial. There are several categories to consider. The most common are centrifugal and diaphragm pumps. Centrifugal pumps are often used for their efficiency in moving large volumes of liquid. This type utilizes an impeller to create flow, making them ideal for applications requiring quick priming.

Diaphragm pumps, on the other hand, work differently. They use a flexible diaphragm to create suction and discharge. These pumps handle viscous fluids and slurries effectively. A report by the Global Pump Market Research indicates that diaphragm pumps are gaining popularity, especially in wastewater treatment sectors, growing at an annual rate of 5%.

Another important consideration is the pump’s material. Pumps made from corrosion-resistant materials are vital when dealing with chemicals. The right material impacts durability and efficiency. Some users overlook this detail. They might pay for a pump that fails prematurely due to material incompatibility. Always double-check the specifications. Your choice should balance performance and longevity. Different needs call for different types. Don’t rush the decision process, or you might regret it later.

Choosing the right self-priming pump involves understanding its specifications. Focus on flow rate, pressure, and materials. Industry reports show that flow rates typically range from 10 to 500 gallons per minute (GPM). This variability suits different applications, from garden use to industrial tasks.

Ensure to select a pump that offers the flow required without compromising efficiency.

Pressure is another critical factor. A pump's pressure rating should match your system's needs. For example, many systems operate effectively at 30 to 80 psi.

Pumps that can handle fluctuating pressures often perform better in dynamic scenarios. Low-pressure pumps may struggle, indicating the need for better options.

Tip: Always check the pump material. Common materials include stainless steel and plastic. Select the one that best fits your fluid type and temperature.

Different materials can impact performance and lifespan, so make careful considerations.

Remember, even with all specs considered, real-world performance may differ. Testing the pump in a practical setting can highlight unexpected issues.

Don't rely solely on manufacturer claims; field data provides a clearer picture of performance. Evaluating this data could save time and resources in the long run.

To ensure your self-priming pump operates efficiently, regular maintenance is essential. Start by checking the fluid levels frequently. Low fluid can lead to overheating or insufficient priming. Clean the pump strainer often to prevent clogging, which can reduce performance. Ensure that all connections are snug to avoid leaks, as even small leaks can cause big issues over time.

Inspect the motor regularly for debris. Dust and dirt can accumulate and impact functionality. Keeping the motor clean can prolong its life. Listen for unusual noises while the pump is running. Strange sounds might indicate mechanical problems. Address these issues sooner rather than later, as neglect may result in costly repairs.

Don't forget to lubricate moving parts as recommended. However, too much lubrication can lead to other problems. It’s a fine balance. Regularly check for wear and tear on components. Sometimes parts need replacing, even if they look fine externally. Maintenance is about catching the small issues before they become big headaches.