In the ever-evolving landscape of industrial applications, the selection of the right centrifugal pump parts is crucial for operational efficiency and reliability. According to a recent industry report by Market Research Future, the global centrifugal pump market is projected to reach $50 billion by 2025, driven largely by advancements in technology and growing demand across sectors such as water treatment, oil and gas, and chemical processing. As organizations strive to optimize performance and reduce downtime, understanding the intricacies of centrifugal pump components becomes indispensable.

Expert insights into the selection process further underscore its importance. Dr. John Smith, a leading authority in pump engineering, emphasizes, "Choosing the right centrifugal pump parts not only enhances system performance but also significantly extends the lifespan of the pump." This statement highlights the need for meticulous consideration of factors such as material compatibility, fluid characteristics, and operational conditions when selecting components.

In summary, the choice of centrifugal pump parts not only impacts immediate operational success but also plays a vital role in the long-term sustainability of industrial systems. As we delve into this topic, understanding the key considerations and industry benchmarks will empower decision-makers to make informed choices that align with their specific applications.

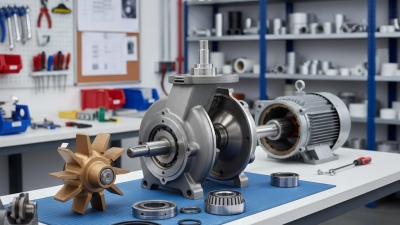

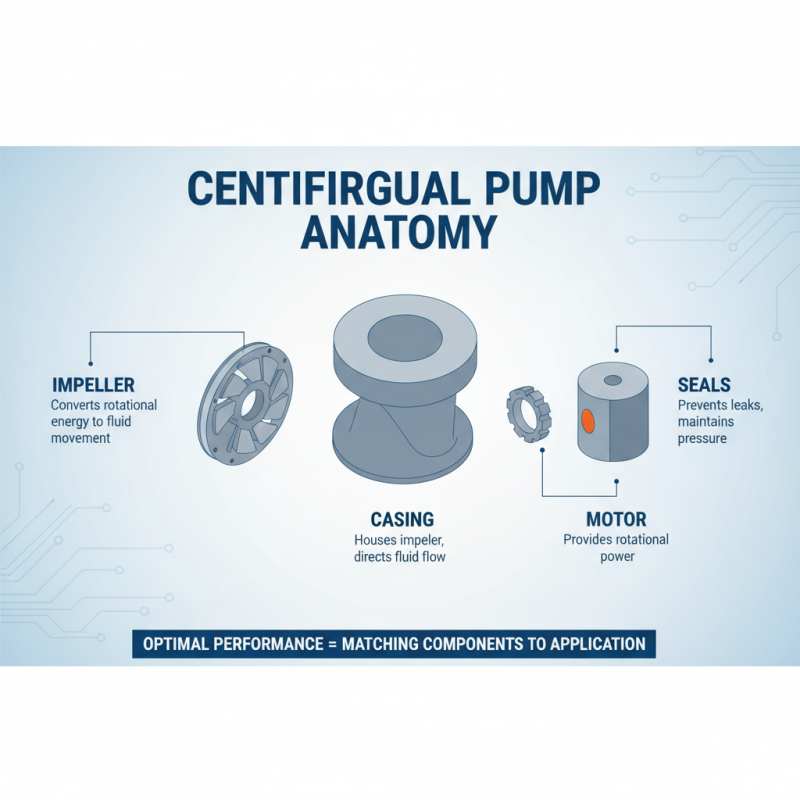

When selecting the right centrifugal pump parts for your application, it is crucial to understand the various components that make up a centrifugal pump. These parts include the impeller, casing, motor, and seals, each playing a vital role in the pump's operation and efficiency. The impeller is responsible for converting rotational energy into fluid movement, while the casing houses the impeller and directs the flow of the fluid. Properly matching these components with the specifications of your application can significantly enhance performance and longevity.

Tips: Always consider the fluid’s properties, such as viscosity and temperature, when choosing parts. Additionally, ensure that the material of the pump components is compatible with the fluid to prevent corrosion and wear.

Another important aspect is the seal type, which prevents fluid leakage and protects the pump from damage. Common seal options include mechanical seals and packing seals, and each type offers distinct advantages depending on the operational conditions. By carefully evaluating your specific needs and the characteristics of the pump parts, you can optimize both the efficiency and reliability of your centrifugal pump system.

Tips: Regular maintenance and inspection of pump parts can help identify potential issues before they lead to significant failures, thereby extending the lifespan of the pump.

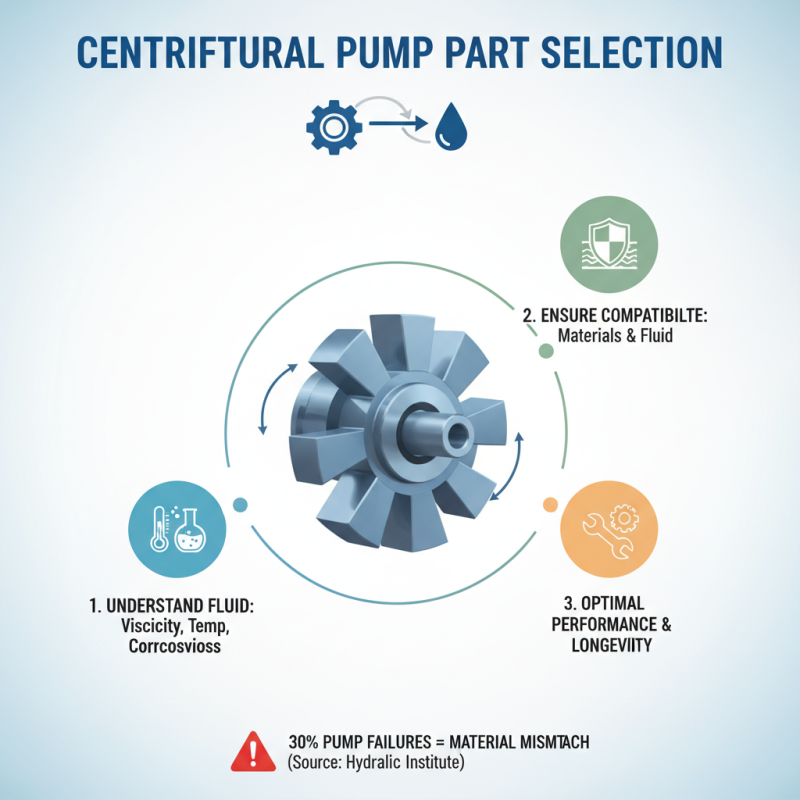

When choosing the right centrifugal pump parts for your specific application, it's crucial to identify your unique requirements before making any decisions. The first step involves understanding the fluid characteristics, which include viscosity, temperature, and corrosiveness. According to a report by the Hydraulic Institute, nearly 30% of pump failures can be attributed to the mismatch between the pump materials and fluid properties. Therefore, ensuring compatibility between the pump construction materials and the fluid is vital for optimal performance and longevity.

Next, consider the operational parameters such as flow rate and head requirements. A study from the American Society of Mechanical Engineers states that improper sizing can lead to significant energy losses and increased operational costs, sometimes exceeding 20% of the total energy consumption attributed to inefficient pump usage. Evaluate your system's demands, including the intended flow rate and how these parameters might change over time. By clearly defining these specific application requirements, you can select centrifugal pump parts that not only function correctly but also enhance efficiency and reliability in the long run.

When selecting the right centrifugal pump parts for your application, evaluating performance factors is crucial. One of the primary considerations is the flow rate, which is the volume of fluid the pump can move within a specific time frame. An adequate flow rate is essential for meeting the demands of your system, ensuring that the pump can handle peak operational conditions without compromising efficiency. Additionally, the pump's head, or the height to which it can elevate the fluid, plays a significant role in determining its suitability for a particular application. It’s vital to calculate the required head based on system characteristics to ensure optimal performance.

Another performance factor to consider is the efficiency of the pump. This includes hydraulic efficiency, volumetric efficiency, and mechanical efficiency. Selecting parts that contribute to higher overall efficiency can lead to reduced energy consumption and lower operational costs. Moreover, operating conditions such as temperature, viscosity, and fluid characteristics must align with the pump's specifications to avoid issues like cavitation or excessive wear. By thoroughly evaluating these performance factors, you can make informed decisions that enhance the reliability and longevity of your centrifugal pump system.

When selecting centrifugal pump parts, the choice of materials is paramount for ensuring both durability and compatibility with the fluids being handled. Various studies indicate that around 70% of pump failures can be traced back to material incompatibility, leading to issues such as corrosion, fatigue, and erosion. Materials must be carefully matched to the specific characteristics of the fluid, including pH levels, temperature, and viscosity, to avoid premature wear or catastrophic failures. For instance, stainless steel is often favored for its corrosion resistance, while polyvinyl chloride (PVC) is commonly chosen for its chemical resistance in handling aggressive fluids.

Tips: Always evaluate the chemical compatibility of the material with the fluid to ensure a long lifespan for your pump parts. Utilize compatibility charts or consult with material experts to prevent costly downtime and repairs.

Furthermore, temperature plays a crucial role in material selection. High-temperature applications, such as those involving hot water or steam, typically require specialized materials like fluoropolymers or reinforced composites. According to industry reports, utilizing materials designed for high-temperature conditions can extend pump life by an impressive 30-50%. Additionally, mechanical properties like tensile strength and flexibility should be assessed, ensuring the material can withstand operational stress without failure.

Tips: Review the manufacturer's specifications regarding temperature ratings and pressure limits when selecting materials for pump components. Properly matching material properties to application demands enhances operational efficiency and reliability.

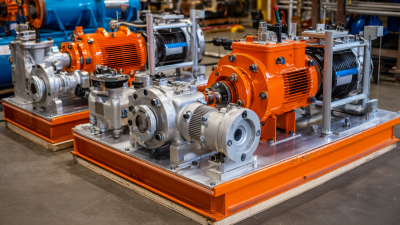

When selecting centrifugal pump parts, sourcing and installation are crucial to ensure optimal performance and longevity. According to industry reports from the Hydraulic Institute, nearly 20% of pump failures can be traced back to improper component selection and installation practices. This highlights the importance of thoroughly understanding both the operational requirements and compatibility of various parts before making a purchase.

When sourcing pump components, it’s essential to consider materials that can withstand the specific operating conditions such as temperature, pressure, and fluid composition. For instance, using stainless steel for corrosive fluids can significantly enhance the pump’s lifespan. Additionally, verifying the supplier’s quality assurance processes can mitigate the risk of defects.

**Tips:** Always request documentation for parts performance and adherence to industry standards. Additionally, perform a risk assessment during the selection phase to identify potential challenges that might arise during installation and operational phases.

The installation of pump parts requires precision and care. Improper alignment or fitting can lead to efficiency losses and accelerated wear. Adopting best practices, such as following the manufacturer's guidelines for torque specifications and utilizing proper lubrication techniques for moving parts, can prevent future operational issues. Regular training sessions for maintenance personnel on installation techniques can further enhance reliability and performance, ensuring that your centrifugal pump runs smoothly for years to come.

**Tips:** Consider using vibration monitoring tools during installation to quickly identify misalignment or imbalance issues before the pump goes live.

| Part Type | Material | Application | Best Practices | Installation Tips |

|---|---|---|---|---|

| Impeller | Stainless Steel | Water Treatment | Choose a design that maximizes flow | Ensure precise alignment during installation |

| Bearing | Bronze | Chemical Processing | Select based on load capacity | Lubricate properly before installation |

| Suction Strainer | Plastic | Irrigation | Choose a size that ensures adequate flow | Clean before installation to prevent clogs |

| Gasket | Rubber | Oil & Gas | Ensure compatibility with fluids | Check for correct placement to avoid leaks |

| Seal | Ceramic | Food Processing | Select based on pressure ratings | Ensure proper fit to avoid contamination |