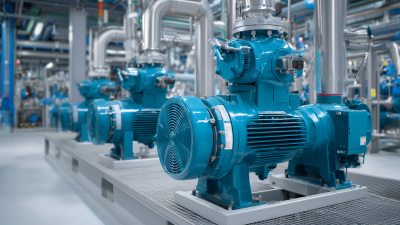

Choosing the right industrial pumps for your business needs is a critical decision that can greatly impact your operational efficiency and productivity. Industrial pumps are essential components in various sectors, including manufacturing, construction, and water treatment, where the effective transfer of fluids is crucial. With a myriad of options available, understanding the specific requirements of your application is fundamental to making an informed choice.

In today’s market, industrial pumps are designed to handle numerous fluid types, ranging from water to viscous chemicals. This diversity necessitates a thorough evaluation of factors such as flow rate, pressure requirements, and fluid characteristics before selection. Additionally, considerations around energy efficiency, maintenance, and overall system compatibility play a significant role in ensuring that the chosen pump optimizes performance and reduces operational costs in the long run. Careful analysis and selection can lead to enhanced productivity and reduced downtime, making it imperative for businesses to invest time and resources in understanding their pumping needs.

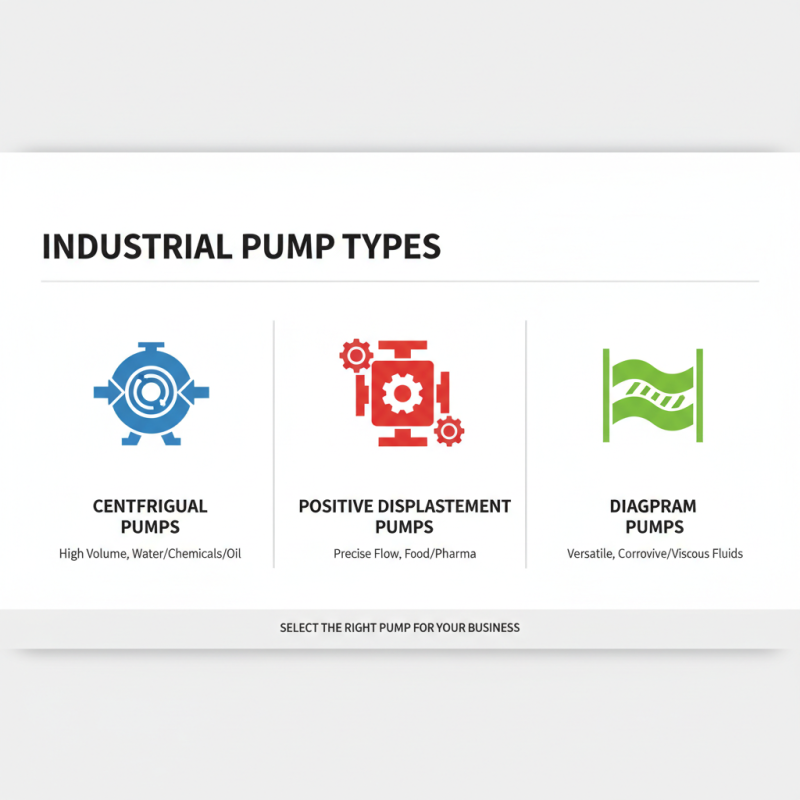

When selecting the right industrial pump for your business, it's essential to understand the various types available and their specific applications. Common categories of industrial pumps include centrifugal pumps, positive displacement pumps, and diaphragm pumps. Centrifugal pumps are widely used for their efficiency in moving large volumes of fluids quickly, making them suitable for water, chemicals, and oil. Positive displacement pumps, on the other hand, are ideal for applications requiring precise flow rates, as they move a fixed amount of fluid with each cycle, which is essential for food processing and pharmaceuticals. Diaphragm pumps offer versatility and can handle corrosive and viscous fluids, making them perfect for specialized industries.

**Tips:** When choosing a pump, consider the fluid properties, such as viscosity, temperature, and chemical compatibility. Additionally, assess the required flow rate and pressure conditions your operations demand. It’s crucial to also think about the pump’s energy efficiency and maintenance requirements to ensure longevity and cost-effectiveness in your industrial operations.

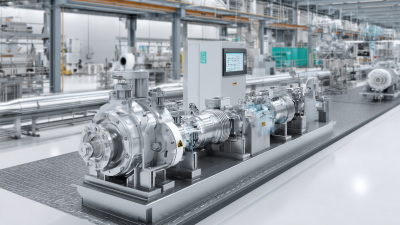

Furthermore, it’s important to evaluate the installation environment of the pump. Some pumps are more suited for harsh settings, while others may require special enclosures or protection. Understanding your business’s unique needs will help you make an informed decision and select the most appropriate pump type for optimal performance.

When evaluating the specific requirements of your business operations, it is crucial to first assess the nature of your processes and the fluids involved. Different industries have unique demands, whether it’s the viscosity of the fluid, temperature conditions, or the level of abrasiveness. For instance, a manufacturing facility handling slurries will need robust pumps capable of managing solid particles, while a food processing plant might prioritize sanitary pump designs that meet strict health regulations. Conducting a thorough analysis of these factors can help narrow down suitable pump types that align with operational needs.

Additionally, understanding the flow rate and pressure requirements is essential in selecting the right industrial pumps. Each application will have specific parameters regarding how much fluid needs to be moved and at what speed, which can affect overall efficiency. By calculating the average demand and considering peak usage periods, businesses can determine the appropriate pump capacity.

Collaborating with engineering or technical professionals can further aid in identifying any unique challenges specific to your operations, ensuring that the chosen pumps contribute positively to performance and reliability in the long run.

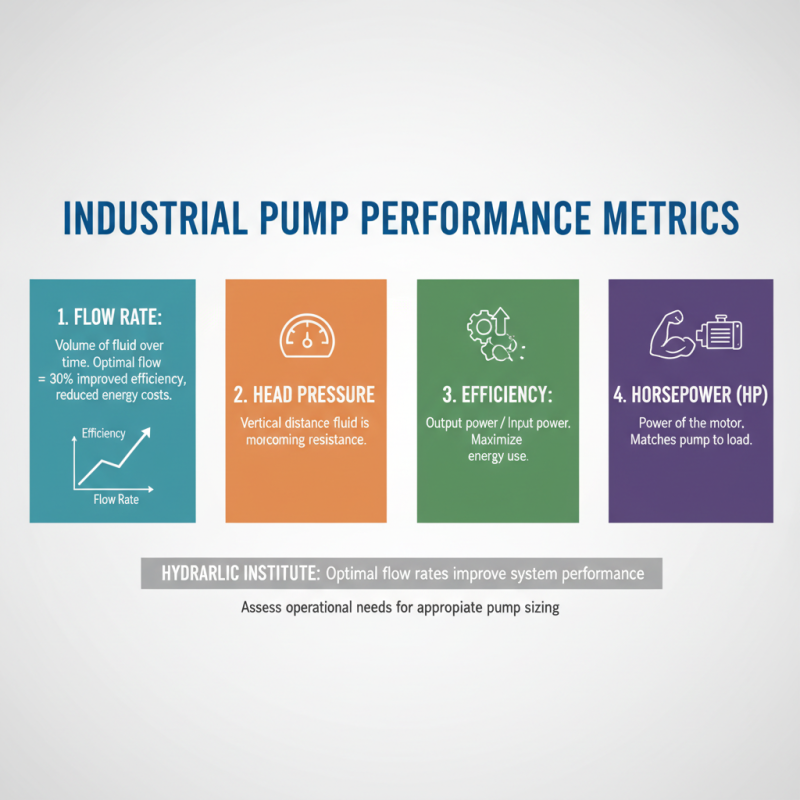

When selecting industrial pumps, understanding performance metrics is crucial for meeting specific business requirements. Key metrics that should be analyzed include flow rate, head pressure, efficiency, and horsepower. A recent report from the Hydraulic Institute indicates that flow rates can significantly influence operational efficiency, with optimal flow rates improving system performance by as much as 30% while reducing energy costs. Organizations must assess their operational needs to determine the appropriate flow rate, as undersized or oversized pumps can lead to inefficiencies and increased operational costs.

Additionally, examining head pressure is vital as it determines how effectively a pump can transport fluid to the desired location. According to a study by the American Society of Mechanical Engineers (ASME), pumping systems that balance head pressure and flow rates can reduce energy consumption by up to 40%. Furthermore, efficiency ratings, such as those measured by the Pump Efficiency Initiative, highlight the importance of selecting pumps with high energy efficiency to minimize operational expenses and extend equipment lifespan. Implementing pumps with performance metrics tailored to specific applications not only ensures optimal operations but also contributes to sustainability efforts by reducing energy consumption and minimizing waste.

When selecting industrial pumps for your business needs, maintenance and support factors are crucial for ensuring long-term functionality and efficiency. It's essential to evaluate the service requirements of the pump you intend to purchase. Consider the frequency of maintenance and the ease with which service can be performed. Pumps that require specialized tools or expertise for routine checks and repairs can lead to increased downtime and operational inefficiencies. Opting for equipment designed with user-friendly maintenance features can significantly lower your long-term operational costs.

Another vital factor to consider is the availability of support from the manufacturer or supplier. This includes not just the warranty and service agreements, but also access to parts and support personnel. An established support system provides reassurance that assistance will be available in case of unexpected issues. Look for suppliers who offer comprehensive service packages, including training for your staff, prompt technical support, and a readily accessible inventory of spare parts. Investing time in understanding these aspects will lead to more informed decisions, ensuring that the pumps selected not only meet your immediate needs but also contribute to a sustainable and efficient operation over time.

When considering the purchase of industrial pumps, one of the primary factors that businesses must address is budgeting. It is essential to strike a balance between the initial costs of acquiring the pumps and their long-term value. While opting for the lowest-priced option might seem attractive initially, this can often lead to higher costs over time due to maintenance, efficiency losses, or even premature failures. Therefore, it is crucial to evaluate the overall lifecycle costs associated with each pump, which includes installation, operation, maintenance, and eventual replacement.

Moreover, businesses should also consider the efficiency of the pumps in relation to their operational requirements. Investing in a slightly more expensive, high-efficiency pump can result in significant savings on energy costs and operational downtime. These pumps may have advanced features that improve their performance and durability, ultimately providing better reliability and requiring less frequent repairs. By focusing on the total cost of ownership rather than just the upfront price, companies can make informed decisions that will support their long-term operational efficiency and financial stability.