When it comes to maintaining an efficient water system, the selection and installation of a priming pump play a critical role. A priming pump is essential in ensuring that the main pump operates smoothly by removing air from the pumping mechanism, thereby preventing cavitation and maintaining prime. According to industry reports, a properly installed priming pump can increase the overall efficiency of a water system by up to 30%, significantly reducing operational costs and enhancing system longevity.

However, the process of choosing and installing a priming pump requires careful consideration of various factors, including system requirements, pump type, and installation conditions. Industry data suggests that improper selection or installation can lead to system failures and costly repairs, emphasizing the importance of understanding the specifications and capabilities of different priming pumps. Additionally, a comprehensive analysis of pump performance metrics and standards is essential in making informed decisions that cater to specific water system needs.

In this guide, we will explore the key aspects of selecting the right priming pump and the best practices for its installation, ensuring that your water system operates at peak performance. By understanding the nuances of priming pumps and applying best practices, you can safeguard your system's efficiency and reliability.

When selecting a priming pump for your water system, it is crucial to assess your specific needs based on factors such as flow rate, head height, and the type of water being pumped. According to the Pumping Equipment Manufacturers Association (PEMA), the selection process starts with determining the system's required flow rate, typically measured in gallons per minute (GPM). For instance, residential applications often require pumps that can deliver between 5 to 25 GPM, while agricultural or industrial systems may necessitate much higher capacities, sometimes exceeding 100 GPM.

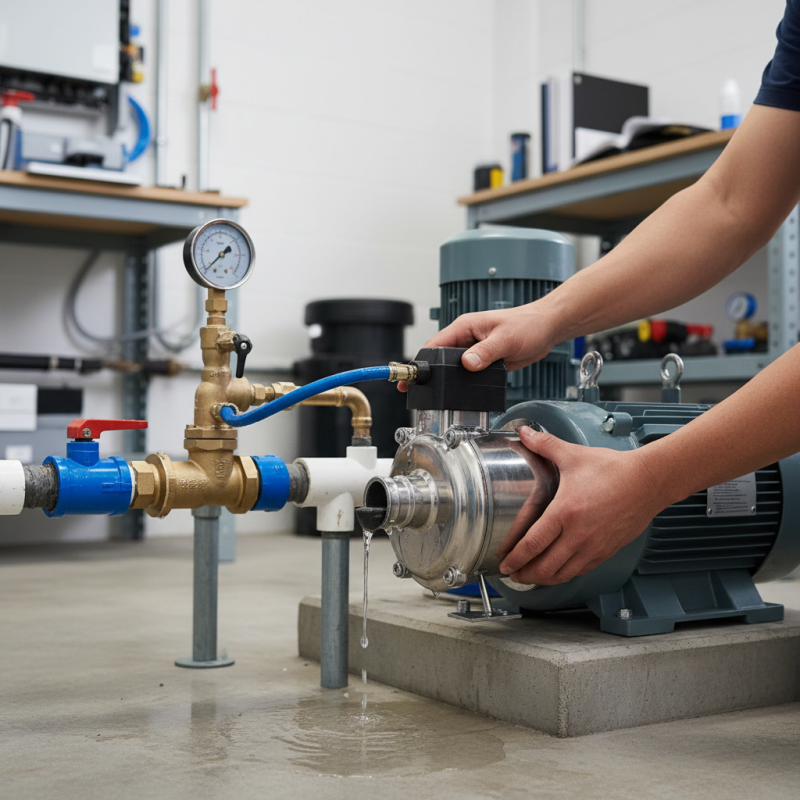

Head height, or the vertical distance that the pump needs to lift water, is another critical consideration. The Hydraulic Institute reports that an optimal priming pump should be capable of overcoming both the static lift and the friction losses in the pipeline. These can significantly vary based on the installation site, so using a pressure gauge can help quantify these needs accurately. Lastly, consider the characteristics of the water being pumped; sediment-laden or corrosive water may require specialized materials to prevent pump wear and failures. Thus, understanding these specifications will ensure that you choose a priming pump that not only meets performance needs but is also durable and efficient in the long run.

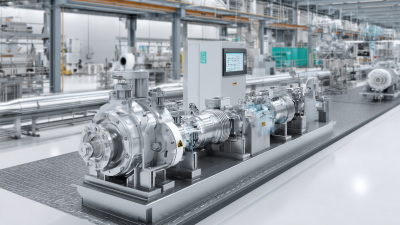

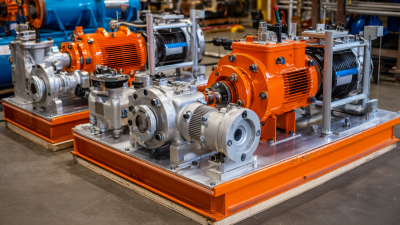

When selecting a priming pump for your water system, it is essential to understand the various types available and their specific design functionalities. Priming pumps generally fall into two main categories: positive displacement pumps and centrifugal pumps.

Positive displacement pumps work by trapping a fixed amount of fluid and forcing it into the discharge pipe, making them highly effective for applications requiring a consistent flow against high pressures. In contrast, centrifugal pumps use rotational energy to move water, making them suitable for low-viscosity fluids and applications where large volumes of water need to be moved quickly.

According to industry reports, these different types of pumps offer distinct advantages depending on the application. For instance, positive displacement pumps can handle viscous fluids better, providing efficacy in systems with thick liquids, while centrifugal pumps are often preferred for their efficiency and ease of maintenance in typical water systems.

Research indicates that selecting the right type of pump can enhance system performance by up to 20%, ultimately leading to significant energy savings over time. Understanding these functionalities allows for optimal decision-making when integrating a priming pump into an existing infrastructure, ensuring reliability and improved operational efficiency within your water system.

When choosing and installing a priming pump for your water system, understanding key performance metrics is crucial. The flow rate, typically measured in gallons per minute (GPM), dictates how efficiently the pump can move water. According to the Hydraulic Institute, an optimal flow rate is essential; for residential systems, a common target might be around 5 to 20 GPM depending on household needs. Evaluating your water system's requirements allows for the selection of a pump that can deliver the necessary volume without causing undue wear or energy waste.

Head height is another critical factor that influences pump selection. This measurement indicates the maximum height the pump can effectively push water, represented in feet. For instance, the American Society of Civil Engineers emphasizes the importance of accurate head height assessment to ensure that the pump can overcome the vertical lift required in your system. A mismatch in this metric can lead to inefficient operation or system failure. Ensuring that your pump's head height rating meets or exceeds the calculated lift requirement is essential to maintaining a reliable water supply.

Finally, pump efficiency is a performance metric that cannot be overlooked. Efficiency, often represented as a percentage, indicates how well a pump converts electrical energy into hydraulic energy. The Energy Information Administration notes that more efficient pumps can result in significant cost savings over time, particularly in systems with high operating hours. Choosing a pump with a high-efficiency rating not only benefits the environment by reducing energy consumption but also contributes to lower energy bills, making it a vital consideration in the selection process.

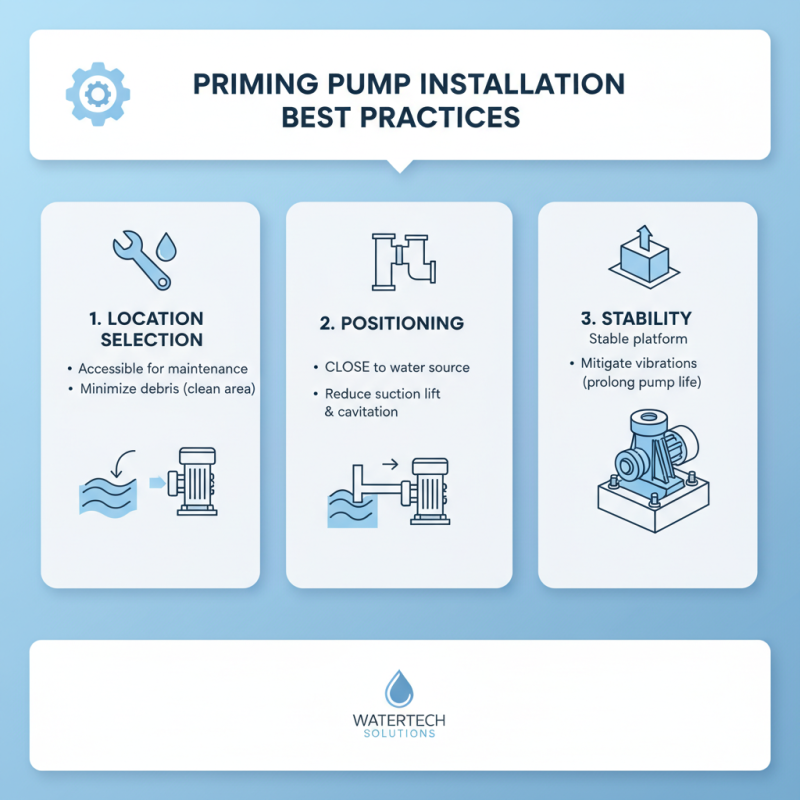

When installing a priming pump for your water system, adhering to best practices is crucial to optimize the pump's performance. Before installation, it's essential to select a location that ensures accessibility for maintenance while also minimizing the risk of debris entering the pump. Position the pump as close to the water source as possible to reduce suction lift and potential cavitation, which can adversely affect performance and longevity. Additionally, ensure that the pump is installed on a stable platform to mitigate vibrations, which can lead to wear over time.

During installation, pay careful attention to piping and connections. Use appropriately sized pipes to prevent excessive friction loss; this will help maintain optimal flow rates. Install check valves and isolation valves to facilitate maintenance and prevent backflow. It's also beneficial to incorporate a strainer or filter to protect the pump from solid particles. Properly sealing all joints and connections will further reduce the risk of leaks, ensuring that the system operates efficiently and effectively. Regularly inspecting the pump and its components will help identify any issues early, allowing for timely maintenance and prolonging the overall lifespan of the system.

Maintaining a priming pump is crucial for ensuring its longevity and reliable performance in your water system. Regular maintenance not only prevents costly repairs but also enhances the efficiency of the pump. According to industry reports, properly maintained pumps can operate up to 10% more efficiently over their lifespan, translating to significant cost savings in energy bills. Key maintenance practices include regular inspection of seals and gaskets for wear and tear, as leaks can lead to reduced efficiency and potential pump failure. Keeping the pump clean and free from debris ensures that it functions optimally, minimizing the risk of corrosion and clogging that can shorten its lifespan.

Additionally, implementing a routine schedule for checking the pump’s operational parameters, such as pressure and discharge rates, is essential. Data from the Pump Industry Association indicates that nearly 70% of pump failures are attributed to inadequate monitoring and maintenance. Addressing signs of wear early can prevent unexpected breakdowns and extend the operational life of the pump significantly. It’s also advisable to keep an accurate maintenance log, which can help in identifying patterns that might indicate further issues, allowing for proactive adjustments before they escalate into larger problems. By prioritizing these maintenance practices, you ensure that your priming pump remains a reliable component of your water system for years to come.

| Parameter | Description | Importance | Maintenance Tip |

|---|---|---|---|

| Pump Type | Choose based on application (e.g., centrifugal, diaphragm) | Affects efficiency and operation | Regularly check for wear and tear |

| Flow Rate | Measured in gallons per minute (GPM) | Critical for system performance | Ensure flow rate matches system needs |

| Pressure Rating | Maximum pressure the pump can handle | Prevents system failure | Test pressure levels periodically |

| Installation Location | Consider accessibility and environmental factors | Affects ease of maintenance | Keep the area clean and accessible |

| Power Supply | Voltage and phase requirements | Ensures reliable operation | Check power connections regularly |

| Warranty | Length and coverage of warranty | Protection against defects | Keep warranty documents accessible |